POSITAL’s upgraded kit encoders offer higher resolution, sleeker packaging

POSITAL’s upgraded kit encoders offer higher resolution, sleeker packaging

December 11, 2023 REDWIRE is news you can use from leading suppliers. Powered by FRASERS.

Posted by FRABA Inc

POSITAL-FRABA, based in Hamilton New Jersey, is the North American member of the international FRABA Group, a family of... Read more

Subscribe

Free REDWIRE e-newsletter

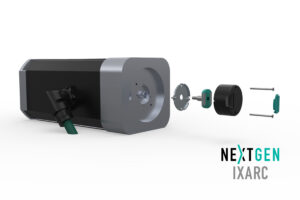

The new generation of kit encoders from POSITAL – designed to be integrated into electric motors, providing position feedback for the control system.

A major upgrade has been announced to the family of 36-millimetre kit encoders available from POSITAL-Fraba: as part of the NEXTGEN initiative, the new devices will come with higher resolution and refined packaging that offers more compact form factors, more protection from solid particles, and easier installation procedures.

The protective cover on each of these kit encoders now measures 19.3 millimetres in height, down from 23.4 millimetres, making them easier to fit within confined spaces.

SSI, BiSS-C communications interfaces

Also known as modular encoders, kit encoders are built for integration into electric motors and other rotating machines, to offer position feedback for the control system. These encoders share many characteristics with POSITAL’s standalone absolute encoders, but are stripped-down designs without separate shafts or bearings. When installed in a motor, a permanent magnet array is attached to the motor shaft, and the measurement module would be attached to the motor housing. This results in a rugged, cost-efficient assembly offering exact feedback on the rotary position, allowing inexpensive BLDC or stepper motors to perform many of the functions of more expensive servomotors. Businesses have used these encoders successfully in thousands of motor and robot installations.

A major innovation in the NEXTGEN kit encoders is the inclusion of tunneling magneto resistance (TMR) technology for rotational position sensing. TMR sensors provide more exact measurement of magnetic field changes, lower temperature sensitivity, and lower energy consumption than previous Hall effect sensors, so the new models have higher resolution and more stable performance over a broad variety of operating conditions. A new ASIC and new-generation Wiegand sensors combine to offer a self-powered rotation counter. With this system, every rotation of the host machine’s shaft is recorded accurately in the encoder’s non-volatile memory, even if rotations happen when system power is unavailable.

Available with SSI and BiSS-C communications interfaces, these upgraded encoders have redesigned packaging that makes installation easier and boosts protection against dust and debris from machining operations. To speed up installation, the number of screws fastening the encoder package to the motor housing has been reduced from four to two.

For more information, contact POSITAL.

Share

Posted by FRABA Inc

POSITAL-FRABA, based in Hamilton New Jersey, is the North American member of the international FRABA Group, a family of... Read more