Festo unveils heavy-duty Cartesian palletizing gantry: Redefining efficiency and cost-effectiveness

Festo unveils heavy-duty Cartesian palletizing gantry: Redefining efficiency and cost-effectiveness

April 4, 2024 REDWIRE is news you can use from leading suppliers. Powered by FRASERS.

Posted by Festo Inc

Innovate today for a new tomorrow For nearly a hundred years Festo has provided proven Industry Leadership, Super... Read more

Subscribe

Free REDWIRE e-newsletter

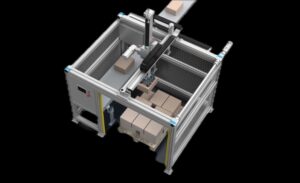

The new Cartesian palletizing gantry by Festo

Festo Canada has introduced a heavy-duty Cartesian palletizing gantry, with a lift capability of up to 200 kilograms (kg) per pick. The gantry includes Z-axis stroke lengths that exceed eight feet and speeds as high as five feet per second. It shortens project time while also lowering engineering and assembly expenses.

Free online design tools, kits for fast assembly, and off-the-shelf servo drives, motors, and other components are among the features of this new Festo solution.

Higher speed and accuracy

Less expensive than six-axis robotic palletizers are, Cartesian gantries provide higher speed and accuracy, whether handling a small load over a long reach or a heavy load over short distances. Six-axis robots lose accuracy and lift capacity at the periphery, but a gantry covers the whole workspace with equal accuracy, speed, and performance at every point on the X and Y axes. Another key advantage is a smaller footprint, which is a boon for today’s smaller, more compact operations.

The core of this gantry is provided by robust, high-rigidity electric actuators – including the tough, cantilevered Z-axis EHMH rack and pinion actuator, for loads up to 200 kg, and the ELCC toothed-belt actuator with ball-bearing guides, for loads up to 100 kg. For an X-axis solution, Festo recommends its EGC-HD heavy-duty tooth-belt or ball-screw actuator for most heavy-duty applications.

For original-equipment manufacturers, system integrators, and end users, Festo’s free Handling Guide Online (HGO) design tool can specify the gantry in 20 minutes or less. Engineers simply input application parameters like distance, speed, torque, and weight, and HGO provides various solution options based on cost and performance. When used in combination with HGO, the Festo Motion Control Package software designs the pre-built control panel; operators connect the cables and program the robot with function blocks, allowing teams to complete initial setup in hours or days.

Other major components for this new Cartesian palletizing gantry include the CMMT-AS servo drive with multi-protocol capabilities, the CPX-E Codesys-based controller for managing multiple synchronized gantries while communicating with third-party controllers, and the CDPX HMI (with an IP67 rating for on-unit mounting.

To learn more, contact Festo.

Share

Posted by Festo Inc

Innovate today for a new tomorrow For nearly a hundred years Festo has provided proven Industry Leadership, Super... Read more