Festo multi-axis cobot system embodies top precision, reliability, and longevity

Festo multi-axis cobot system embodies top precision, reliability, and longevity

June 23, 2022 REDWIRE is news you can use from leading suppliers. Powered by FRASERS.

Posted by Festo Inc

Innovate today for a new tomorrow For nearly a hundred years Festo has provided proven Industry Leadership, Super... Read more

Subscribe

Free REDWIRE e-newsletter

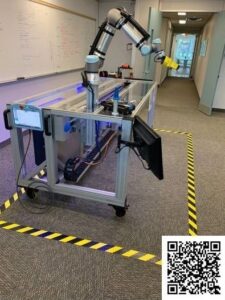

The Festo UR multi-axis system controls up to four axes: UR cobot, top center, with optional E30 smart magnetic gripper: teach pendant, left: and the seventh axis, bottom center. (QR code for virtual-reality image)

Among the latest industrial innovations available from Festo Canada is a multi-axis system for use with Universal Robots (UR) collaborative robots, or “cobots”. Certified by UR+, this ready-to-install solution adds up to four axes of motion beyond the standard six axes on cobots, reducing customer engineering time and speeding startup.

Festo showcased this multi-axis system, which embodies top precision, reliability, and longevity, at the recent Automate 2022 trade show in Detroit.

No setup programming involved

Like all cobot operations, this product is deliberately designed to be easy to configure and operate; no programming is involved in setup, and no extra PLC is necessary. Users can configure the multi-axes through the UR HMI, and it is simple to set position, speed, and acceleration on the HMI – and move the axes in manual mode to configure motion by using the URCap toolbar.

The multi-axis system features the Festo Motion Control Package for UR, or FMCP. This is a complete motion-control panel for motion of up to four axes. The package is fully integrated with the UR cobot control panel and HMI and has a UR safety input/output and communications interface. The FMCP offers a seventh axis for linear transfer; it also controls turning tables, automatic storage systems, conveyors, and transfer tables, all under the UR umbrella. To reduce footprint, it also provides additional space in the panel for future expansion and brackets for wall mounting.

This seventh axis is also useful for expanding the action range for a UR cobot in palletizing, machine tending, and other applications. Sized for longevity, EGC belt-driven or ball-screw linear axes each come with a cobot mounting plate. The EGC series features an energy chain for cable management and servo motor optimized for performance. Festo carries standard EGC axes in lengths of up to eight metres, and users can request axes up to ten metres long.

Also available for use with this solution is a broad variety of grippers, like vacuum, mechanical, and Magswitch magnetic grippers – as well as the E30 cobot smart gripper. Festo also carries automatic tool changers.

For more information, contact Festo.

Share

Posted by Festo Inc

Innovate today for a new tomorrow For nearly a hundred years Festo has provided proven Industry Leadership, Super... Read more