ABCO Industries has pioneered steam blanching for preserving frozen-vegetable flavour

ABCO Industries has pioneered steam blanching for preserving frozen-vegetable flavour

September 28, 2023 REDWIRE is news you can use from leading suppliers. Powered by FRASERS.

Posted by Firing Industries Ltd

The business objective of FIRING INDUSTRIES LTD. is to consult with clients to select and supply technically complex PRO... Read more

Subscribe

Free REDWIRE e-newsletter

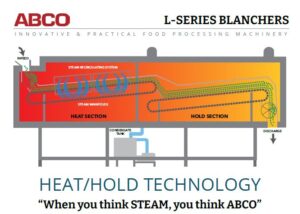

The design of an ABCO steam blancher

Firing Industries Ltd. recently began supplying products by ABCO Industries Inc., a major manufacturer of washers, blanchers, and rehydrators for food-processing applications. ABCO is renowned as a pioneer in the technology of steam blanching – which was invented by the company’s own Graham Gerhardt more than 30 years ago.

Today, steam blanching remains the leading technology for enhancing shelf life and sealing in flavour for many frozen vegetables on the market.

Heat and hold system

Heat penetration to the centre core of any food product is a function of time and temperature; the shorter the duration in the heat medium, the better colour and nutrients are retained. Pure steam blanchers by other manufacturers keep vegetables in the heat medium until the device achieves the desired centre core temperature, and this overcooks the outer part of the product by ignoring the time factor in heat penetration. The unique ABCO L-Series of steam blanchers, available through Firing Industries, uses a heat and hold system that introduces only the sufficient amount of steam into the heat chamber to heat the product surface. This surface heat penetrates through the food in the hold chamber, increased the centre core temperature to the desired blanch level without adding more steam.

Other advantages of this series of steam blanchers: lower operational expenses; reduced water consumption; environmental friendliness; superior colour, flavour, and texture; more nutrients retained, less biochemical oxygen demand and chemical oxygen demand, and less solids, which reduces the level of organic compounds in the water. In addition, the L-Series is simple to install, operate, and maintain.

The main frame of each L-Series unit has separate heat and hold sections and is built from stainless steel, double-skinned with a seven-centimetre-thick wall and fully insulated for optimum energy efficiency. Large access doors over the full length of the device on both sides, plus end doors, enable unlimited access to all machine internals for maintenance and cleaning. Each conveyor has an independent AC variable-speed drive for fine-tuning retention times in both the heat and hold sections.

To learn more, contact Firing Industries’ application-sales engineers at ddubuc@firing.com or (877) 688-0974.

Share

Posted by Firing Industries Ltd

The business objective of FIRING INDUSTRIES LTD. is to consult with clients to select and supply technically complex PRO... Read more