Wilden’s chemical solutions: AODD pumps redefine efficiency, safety, containment

Wilden’s chemical solutions: AODD pumps redefine efficiency, safety, containment

February 28, 2024 REDWIRE is news you can use from leading suppliers. Powered by FRASERS.

Posted by John Brooks Company Limited

John Brooks Company Limited: Fluid Handling Solution providers since 1938. For over 80 years, John Brooks Company has pr... Read more

Subscribe

Free REDWIRE e-newsletter

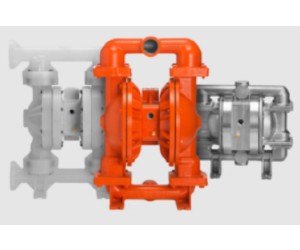

The Pro-Flo SHIFT series of AODD pumps by Wilden

John Brooks Company Limited is the name to trust for air-operated double-diaphragm (AODD) pumps by Wilden. This includes models designed for chemical process applications. Wilden’s AODD pumps are ideal for this field because they improve operational efficiency while being able to handle most chemicals.

Not only do they outperform competing technologies in terms of dependability and cost-efficiency; Wilden AODD pumps also prevent leakage and cross-contamination.

Versatile and simple to maintain

Businesses that use chemical-based compounds like caustics, acids, solvents, or polymers know the production process relies on valuable chemicals. If not handled properly and contained correctly, these chemicals can be extremely hazardous and harmful to employees, the environment, and the productivity of the operation. So it is absolutely crucial to select equipment that can rise to the challenges inherent in the production, transfer, transport, and containment of chemical configurations.

Wilden AODD pumps are up to the challenge, and they offer the following features and advantages: versatility; simple maintenance; leak-free and seal-less design; run-dry capability; high suction lift; portability; and energy savings. John Brooks Company recommends them for several chemical process applications, including acid transfer, polymer transfer, chemical dosing, low-solvent coating, and solvent transfer.

The following Wilden solutions work for chemical process applications:

- Pro-Flo SHIFT series. These bolted metal and plastic pumps offer up to 60 per cent energy savings, up to 34 per cent higher flow rates, fewer operating parts (which means less downtime and easier maintenance), longer diaphragm life, quiet operation, and better containment.

- Chem-Fuse integral piston diaphragms. These pump components eliminate potential leak points at outer pistons, as well as outer piston abrasion for longer diaphragm life, when pumping critical or hazardous liquids. Simple to clean, for quicker changeovers between products.

- Velocity specialty series. Compact units with a full bore-seal design that eliminates potential effects of torque decay. Numerous mounting configurations to comply with any application; high suction lift, for dependable operation and any air pressure; low startup pressure.

Watch this video for a demonstration:

For more information, contact John Brooks Company.

Share

Posted by John Brooks Company Limited

John Brooks Company Limited: Fluid Handling Solution providers since 1938. For over 80 years, John Brooks Company has pr... Read more