Festo’s HPPF: Gripping innovation for small spaces, redefining assembly

Festo’s HPPF: Gripping innovation for small spaces, redefining assembly

January 2, 2024 REDWIRE is news you can use from leading suppliers. Powered by FRASERS.

Posted by Festo Inc

Innovate today for a new tomorrow For nearly a hundred years Festo has provided proven Industry Leadership, Super... Read more

Subscribe

Free REDWIRE e-newsletter

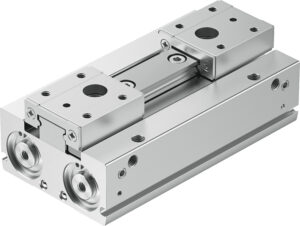

Twin-piston rack and pinion motion and ball-bearing guides give Festo’s new HPPF parallel grippers high accuracy (≤ 0.03 mm to ≤ 0.06 mm), high gripping power, and maintenance-free long-service life.

The latest industrial solution by the Festo Canada team is the HPPF, a diminutive flat parallel gripper that is developed specifically for space-constrained applications. Due to manufacturing innovations achieved on a new production line, this unit delivers great force in confined spaces – and does so at an affordable cost.

The HPPF comes highly recommended for space-constrained tasks in small-parts and electronics assembly, including battery manufacturing, thanks to its unique compact design.

High accuracy and long life

Festo is offering the HPPF gripper in four different sizes – eight, 12, 16, and 20, ranging from 19 to 41 millimetres (mm). The stroke ranges from a narrow eight to a wide 80 mm, while gripping forces go from 60 to 377 newtons. These sizes are ideal for small-parts and electronics assembly applications, and since the unit contains less than one per cent copper, zinc, and nickel, it is also perfect for battery production.

The high accuracy of the HPPF (from less than or equal to 0.03 to less than or equal to 0.06 mm) and its maintenance-free, long-service life stem from the twin-piston rack and pinion motion and the ball-bearing guides. The twin pistons provide a high grip force for this compact unit, which is symmetrical to enable higher flexibility in mounting. Both sides of this diminutive flat parallel gripper have C-slots for sensors, and machine builders can adjust the stroke; there is also an elastic cushioning option. The exceptionally low weight is a perfect fit for the smaller footprint of contemporary manufacturing operations, which require more sustainable equipment; the weight ranges from 68 grams to 1.326 kilograms.

The gripper is ideal for use in any applications in which an extremely flat design is mandatory, including special machine construction. Other key benefits of the Festo HPPF: its durability, with an integrated guide and robust design; its top price-to-performance ratio; its combinable quality, due to the various sizes and strokes available; and its sustainability, via reduced material use and minimal maintenance over its entire service life.

Based in Mississauga, Ont., Festo Canada remains a leading supplier of automation technology.

For more information, contact Festo.

Share

Posted by Festo Inc

Innovate today for a new tomorrow For nearly a hundred years Festo has provided proven Industry Leadership, Super... Read more