Daemar industrial braided packing and how it prevents fluid loss

Daemar industrial braided packing and how it prevents fluid loss

January 6, 2021 REDWIRE is news you can use from leading suppliers. Powered by FRASERS.

Posted by Daemar Inc.

Daemar manages the sourcing and delivery of millions of Essential Components to the manufacturing and MRO marketplace. I... Read more

Subscribe

Free REDWIRE e-newsletter

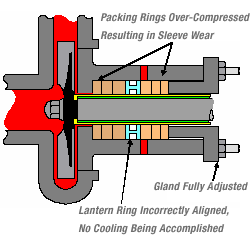

An illustration of how braided packing can fail if it is not installed properly.

Essential components for industry: this is what customers get from Daemar Inc. One useful solution available is industrial braided packing. This product is used as a seal to restrain leaks around rods, shafts, valve stems, and other working parts in machinery that require fluid or gas containment.

Packing failures often result from incorrect installation. Installing braiding packing on pumps the right way will ensure optimal performance.

Selecting the right cross-section

Industrial braided packing is popular in steel and paper mills, petrochemicals, utilities, water and wastewater treatment, food processing, and nuclear power. Organizations use it to seal water, steam, gases, caustics, solutions, acid, oil, gasoline, and other substances over a broad range of temperatures and pressure conditions.

Easy to install and maintain, industrial braided packing delivers successful operation with proper care. Daemar offers the following advice:

- Remove old packing from the packing box. Clean the box and shaft, and check the shaft and sleeves for wear or scoring. Replace extremely worn shafts and sleeves.

- Choose the correct cross-section of packing or die-forming rings. Measure the shaft diameter and the diameter of the packing box, then subtract the former from the latter and divide it by two: this determines the required size.

- If using a coil or spiral packing, cut it into separate rings. Never turn a packing coil into a packing box. Depending on the construction, users can cut rings with the butt, bias, or diagonal joints. The most reliable method is to cut them on a mandrel with a diameter equal to that of the shaft in the packing-box area.

- Install one ring at a time. Make sure the packing is clean. Place rings securely and keep the joints of succeeding rings staggered and at least 90 degrees apart.

- Take up bolts finger-tight or slightly snugged up after installing the last ring. Turn on the pump and take up bolts until leakage is at a bearable minimum.

- Permit the packing to leak freely when using a newly packed pump. Never try to halt leakage completely unless it is safe to do so.

To learn more, contact Daemar.

Share

Posted by Daemar Inc.

Daemar manages the sourcing and delivery of millions of Essential Components to the manufacturing and MRO marketplace. I... Read more