Vibra Finish Limited Is Skilled with Several Different Kinds of Finishing Methods

Vibra Finish Limited Is Skilled with Several Different Kinds of Finishing Methods

January 20, 2022 REDWIRE is news you can use from leading suppliers. Powered by FRASERS.

Posted by Vibra Finish Limited

Vibra Finish Limited is a manufacturer of vibratory finishing, centrifugal finishing, tumbling, separating, vibro-peenin... Read more

Subscribe

Free REDWIRE e-newsletter

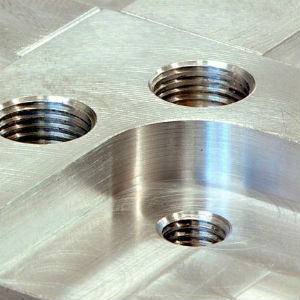

Metal finishing equipment and blasting equipment are among the systems Vibra Finish Limited uses.

For top-quality finishing of metal parts, businesses have relied on Vibra Finish Limited for close to half a century. One of the company’s advantages is its skills with different kinds of finishing methods. The Vibra Finish Limited team serves its customers with a variety of finishing equipment for the best results.

From metal finishing vibratory machines to parts washers and shot blasters, Vibra Finish Limited has plenty of equipment in its facility to handle a wide range of finishing systems.

Easy for users to operate

For deburring or removing rough edges from machine parts, Vibra Finish Limited recommends metal finishing equipment. Easy for users to manipulate and operate, this equipment typically includes replaceable polyurethane liners. This system is suitable for fabricated aluminum and steel, bronze water-meter housings, aluminum die-cast heat sinks, and similar applications; it can also improve the surface finish of a titanium valve.

Another of the company’s finishing methods is blasting equipment, which employs controlled blasts that pose no safety risks to users. The two types of blasting for metal finishing are air blasting and wheel blasting. Air blasting is suitable for deburring, de-flashing, or etching surfaces, as well as blast cleaning and shot peening. Wheel blasting, meanwhile, is preferable for surface cleaning and etching, structural steel, casting and cleaning, automotive-part remanufacturing, and wire descaling.

These are not the only finishing methods Vibra Finish Limited uses. The company also employs industrial parts washers for surface preparation. These washers assist in quicker, more effective disposition of all cleaning-related tasks, and they can be used with gas, steam, or electric heating units. For wood or metal, Vibra Finish Limited recommends lathes, which are machining tools that hold work pieces and rotate them with cutting tools. One common variation, the grinder, is essential for polishing surfaces.

One more key ingredient in finishing procedures is abrasives. These are substances that are used for smoothing or polishing surfaces through scraping. Examples of these substances include ceramic, steel and plastic media. Finally, popular finishing accessories include alarms, remote controls, and operator safety equipment.

With this range of equipment, Vibra Finish Limited helps many businesses complete the final stages of their manufacturing production.

To learn more, contact Vibra Finish Limited.

Share

Posted by Vibra Finish Limited

Vibra Finish Limited is a manufacturer of vibratory finishing, centrifugal finishing, tumbling, separating, vibro-peenin... Read more