Versa-Matic metal AODD pump offers top efficiency, high flow rates

Versa-Matic metal AODD pump offers top efficiency, high flow rates

September 17, 2020 REDWIRE is news you can use from leading suppliers. Powered by FRASERS.

Posted by York Fluid Controls Ltd

Is a leading stocking distributor of fluid transfer and process pumps, positive displacement and centrifugal pumps, liqu... Read more

Subscribe

Free REDWIRE e-newsletter

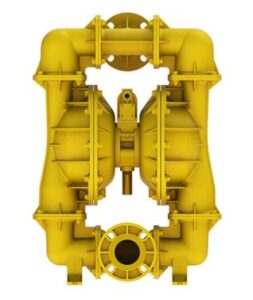

The Versa-Matic three-inch bolted metal AODD pump

York Fluid Controls is Canada’s source of air-operated double-diaphragm (AODD) pumps by Versa-Matic. For applications that involve harsh chemicals, Versa-Matic recommends its three-inch bolted metal AODD pump – a unit that uses optimized casting designs to maximize efficiency, while delivering high flow rates, strong solids handling, and simple, inexpensive maintenance.

This chemical-resistant pump meets all fluid-transfer needs quickly and reliably, with the highest flow of all Versa-Matic metal AODD products.

With a leak-free design

Suited for many applications, this metal AODD pump is ATEX-compliant and has a leak-free design that decreases downtime and ensures constant operation. Among its beneficial features are durable and robust castings, extended-life diaphragms, multiple connection and porting types, and multiple air section materials available for maximum chemical compatibility.

Technical specifications for this pump from York Fluid Controls: flow rate of up to 1,033 litres per minute; post size of three inches ANSI 150 pounds Class (DIN80), for both suction and discharge; air inlet of ½ an inch NPT; air exhaust of one inch NPT; suction lift of 4.9 metres (dry) and 9.4 metres (wet); maximum solid size of 9.5 millimetres in diameter; maximum noise level of 93 decibels; and shipping weight of 66.2 kilograms (aluminum) or 111.1 kilograms (stainless steel), with 22.7 kilograms extra for the stainless centre.

This metal AODD pump was the perfect solution for an industry-leading chemical manufacturer in South Carolina that was expanding its facility. The company required replacements for older, nearly obsolete pumps that lacked reliability and energy efficiency. The new pumps needed to have updated technology, and they would be run by three 75-horsepower air compressors. Most importantly, these new pumps had to be resistant against every chemical that the plant used during production.

The three-inch metal pumps met these requirements perfectly, while working more efficiently and meeting flow and pressure needs. Since installing these Versa-Matic pumps, the manufacturer has saved about $50,000 a year through their energy efficiency, versatility, and utility company grants. Plant managers could save energy by shutting off one of the air compressors instead of buying an additional one.

For more information, contact York Fluid Controls.

Share

Posted by York Fluid Controls Ltd

Is a leading stocking distributor of fluid transfer and process pumps, positive displacement and centrifugal pumps, liqu... Read more