Union Process lab testing services match processing mills to applications

Union Process lab testing services match processing mills to applications

January 26, 2019 REDWIRE is news you can use from leading suppliers. Powered by FRASERS.

Posted by Firing Industries Ltd

The business objective of FIRING INDUSTRIES LTD. is to consult with clients to select and supply technically complex PRO... Read more

Subscribe

Free REDWIRE e-newsletter

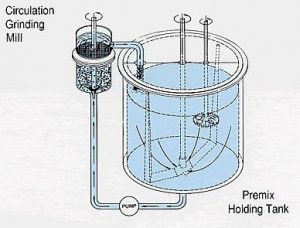

How a circulation grinding mill operates

For nearly a century, Union Process has developed innovative grinding and milling solutions for industrial users – including Canadian customers, who get these products through Firing Industries. The manufacturer makes processing mills for different applications in food processing, metals, pharmaceuticals, and other industries requiring small particle sizes.

To match the right processing mills to specific materials, Union Process maintains a fully equipped research and development lab, where milling experts conduct trials.

Three types of processes

Businesses are encouraged to schedule milling trials at the lab, to determine appropriate solutions for their particle-size-reduction needs. The Union Process website includes forms to submit for trials.

Firing Industries supplies Union Process mills that offer three types of processes: batch-size, circulation, and continuous. In batch-size production, the user places the material with grinding media into a stationary, jacketed tank, and a rapidly rotating shaft agitates them. The media exerts shearing and impact forces on the material, creating optimum size reduction and dispersion. These processing mills have specially designed two-speed electric motors.

A circulation grinding mill blends a grinding mill with a large holding tank. The mill contains grids that restrain the media as the slurry passes through. The unique feature is the high circulating rate: the holding-tank contents pass through the mill about eight times an hour. The high pumping rate leads to quicker grinds and narrower particle-size distribution. Unlike in a continuous machine with the slurry making a single pass, the circulation process sends material through the grinding chamber in many passes until it reaches the desired particle size.

Continuous grinding mills have a compact vertical design for continuous production of large quantities. The mill pumps premixed slurry through the bottom and discharges it at the top of a tall, narrow, jacketed tank with internally agitated media. The time the material stays in the grinding chamber determines the fineness of the resulting material.

To get an idea of how the Union Process testing lab operates, check out the video below.

To learn more, contact Firing Industries’ application-sales engineers at ddubuc@firing.com or (877) 688-0974.

Share

Posted by Firing Industries Ltd

The business objective of FIRING INDUSTRIES LTD. is to consult with clients to select and supply technically complex PRO... Read more