Understanding pipe stiffness: PVC versus ductile iron

Understanding pipe stiffness: PVC versus ductile iron

November 24, 2014 REDWIRE is news you can use from leading suppliers. Powered by FRASERS.

Posted by IPEX Management Inc.

IPEX Inc. designs and manufactures one of the world’s most diverse lines of integrated thermoplastic piping system... Read more

Subscribe

Free REDWIRE e-newsletter

Pipe stiffness is the measure of a flexible pipe’s resistance to deflection under load. A flexible pipe is any pipe that can deflect two per cent without suffering damage. Both ductile iron (DI) and PVC meet this requirement and are considered flexible pipes. However, some specifications require DI pipe due to its “strength” in resisting external loads. While this was true in the era of thick-walled DI Class pipe, the thinner walls of DI Pressure Class pipes have made PVC the stronger option.

Deflection limits

PVC pipe is able to deflect 30 per cent before experiencing failure (by reverse curvature). AWWA C605 (pressure pipe) and ASTM D3034/F679 (gravity pipe) limit PVC pipe deflection to 7.5 per cent, providing a 4:1 safety factor.

On the other hand, DI pipe deflections are significantly limited by the linings used. For example, cement-mortar (gravity sewer and pressure water pipe) has a maximum allowable deflection of three per cent due to potential cracking of the lining. The safety factor is 2:1. Meanwhile, flexible lining (gravity sewer and force-main sewer pipe) has a maximum allowable deflection of five per cent due to potential damage to the lining. The safety factor is 2:1.

Therefore, DI pipe fails at a lower deflection than PVC pipe, and DI has a lower safety factor against failure.

Pipe stiffness

Pipe stiffness (PS) is calculated using the equation: PS = 6.7 EI / r3 where: E = modulus of elasticity (psi); I = moment of inertia (in4/in); and r = mean diameter (in).

Pipe geometry is used to calculate I and r. Modulus values are E = 400,000 psi for PVC and 24,000,000 psi for DI.

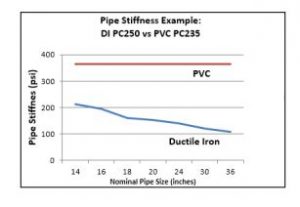

The chart to the right compares pipes of about the same pressure class (PC): DI PC250 pipe and PVC PC235 pipe. In this example, for the 14-inch size, PVC has 1.7 times DI’s pipe stiffness. For the 24-inch pipe, PVC has 2.6 times the stiffness. And for the 36-inch size, PVC is 3.4 times as stiff.

In conclusion, for this example, PVC pipe is the stronger pipe. PVC PC235 pipe has more pipe stiffness (and therefore will deflect less) than DI PC250 pipe, and PVC pipe can safely withstand about five times as much deflection as cement-mortar lined DI pipe.

For more information, contact IPEX Inc., a Mississauga, Ont.-based company that designs and manufactures integrated thermoplastic piping systems.

Share

Posted by IPEX Management Inc.

IPEX Inc. designs and manufactures one of the world’s most diverse lines of integrated thermoplastic piping system... Read more