Trash belt conveyor by Hytrol is perfect for waste, recyclables

Trash belt conveyor by Hytrol is perfect for waste, recyclables

January 24, 2019 REDWIRE is news you can use from leading suppliers. Powered by FRASERS.

Posted by Norpak Handling Limited

Norpak Handling provides conveying products and complete turn-key systems to suit your requirements and solve your probl... Read more

Subscribe

Free REDWIRE e-newsletter

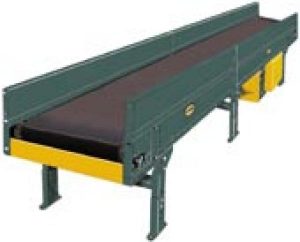

The Hytrol Model TH trash belt conveyor, available in Canada from Norpak

Norpak Handling remains a proud Integration Partner with Hytrol Conveyor Company, a major provider of material-handling products. While conveyor systems are typically used for moving products in manufacturing plants and warehouses, another important purpose is to transport the waste products that result from daily operations, like paper trash and cardboard boxes. This is why Hytrol has developed the Model TH trash belt conveyor – specifically designed to handle paper trash and cardboard.

A unique trash solution

A unique solution for moving recyclables and waste, the Model TH saves precious man hours for workers. Hytrol has constructed this trash belt conveyor for paper waste, empty cardboard containers, and similar items. Its features and advantages include the following:

- centre drive standard;

- steel slider bed, bolted between two steel side channels with 15-centimetre high guards;

- energy-efficient motor, capable of speeds from one to two horsepower;

- adjustable floor supports;

- belt widths ranging from 29 to 134 centimetres; and

- ability to carry loads of up to 4.5 kilograms per linear foot.

Also available through Norpak are optional, MS-style floor supports with a wide range of adjustment and holes in the feet for lagging to the floor. Users can connect other optional equipment to this trash belt conveyor, such as the following: a noseover, or fixed nose for transitioning items from an inclined belt to a horizontal one; a two-pulley hitch for moving things from inclined to horizontal belts; extra side guards, from 30 to 60 centimetres high or flared versions from 15 to 30 centimetres; variable belt speeds; side-mounted end drives with underside take-up; manual or pneumatic underside take-up; O-ring drive chains, sealed in lubricant; poly-tier supports, with support heights from 91 to 300 centimetres, in 15-centimetre increments and with knee braces; and fully threaded ceiling hangers with unplated rods, 2.4 metres long with diameters of 1.5 centimetres.

Another option is electrical controls, such as a manual start switch, non-reversing starters, push-button stations, and an AC variable-frequency drive.

For all material-handling applications, trust Norpak, a top Canadian provider of conveyor solutions and components.

For more information, contact Norpak Handling.

Share

Posted by Norpak Handling Limited

Norpak Handling provides conveying products and complete turn-key systems to suit your requirements and solve your probl... Read more