The two main categories of foam material technology that CFS uses

The two main categories of foam material technology that CFS uses

August 26, 2020 REDWIRE is news you can use from leading suppliers. Powered by FRASERS.

Posted by Custom Foam Systems Ltd.

An Industry Leader In Engineering And Manufacturing Of Fabricated And Moulded Polyurethane Foam Components For A Diversi... Read more

Subscribe

Free REDWIRE e-newsletter

CFS has access to a wide variety of foam material.

Custom Foam Systems Ltd. (CFS) can produce a plethora of foam components for industrial use, and one of its primary advantages is access to a full arsenal of polyurethane foam material. The company’s experienced manufacturing team skillfully fabricates or moulds them to meet any customer’s most demanding needs.

With its proprietary inventory-management system, CFS always has the required materials at hand, along with backup provisions, to respond to any client needs.

Fabricated and moulded materials

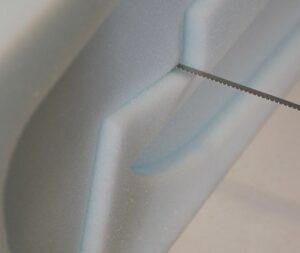

With its volume and strategic partnerships with key suppliers, CFS gets competitive prices for raw foam material. The company has even pioneered the development of a specialized material, Gelfoam, which has a tough outer skin with an intriguing soft touch and slow recovery feel. CFS works with two main material technologies: fabricated materials technology, and moulded materials technology.

With fabricated materials technology, CFS uses polyurethane foam, polyethylene foam, visco-elastic memory foam, pressure-sensitive-adhesive (PSA) backed polyurethane foam, and sewn covers. The polyurethane foam has a 1-2.8 PCF density range, a 10-120 IFD compression range, and California and FMVSS302 flammability. It has the capability to formulate foam grades to meet manufacturer specifications, and anti-microbial grades are available. Polyethylene foam has a 1½-6 PCF density range, with multiple colours and compressions. It can be cross-linked or non-cross-linked, with anti-scratch and pink anti-static qualities.

Visco-elastic memory foam offers excellent performance at extreme temperatures, with a 2-6 PCF density range and 9-25 IFD compression range. PSA backed polyurethane foam has high tack and peel strength and meets automotive VOC emission standards.

Moulded materials technology works for moulded flexible HR foam, moulded integral self-skinning foam (ISKIN), NVH foam material, and visco-elastic integral skin foam. Moulded flexible HR foam is MDI-based and water-blown, with a 2.8-5 PCF density range and 20-60 ILD at 25 per cent compression range. ISKIN is an alternative blowing agent that can successfully disinfect ISKIN surfaces with Virox, alcohol, and bleach solutions. NVH foam offers insulation from inherent vehicle noise and vibration/noise harshness, and it is scientifically developed to be ideal for wide temperature ranges in dry, wet, or humid environments.

For more information, contact CFS.

Share

Posted by Custom Foam Systems Ltd.

An Industry Leader In Engineering And Manufacturing Of Fabricated And Moulded Polyurethane Foam Components For A Diversi... Read more