The top factors in bucket elevator selection from Continental Conveyor

The top factors in bucket elevator selection from Continental Conveyor

March 30, 2020 REDWIRE is news you can use from leading suppliers. Powered by FRASERS.

Posted by Continental Conveyor Ltd

Continental Conveyor, established in 1963, specializes in the design, engineering, and manufacturing of mechanical bulk... Read more

Subscribe

Free REDWIRE e-newsletter

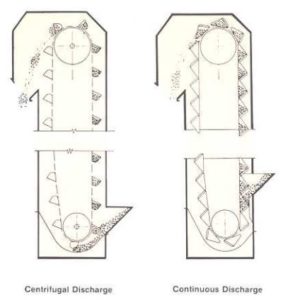

Two types of bucket elevators made by Continental.

Continental Conveyor Ltd. is a major source of material-handling systems, including bucket elevators. These are efficient and reliable products for elevating almost any loose bulk material from 300 mesh to five inches in lump size. Businesses should take several factors into account before choosing new equipment in which to invest. This goes for bucket elevator selection. Continental Conveyor offers helpful advice on picking a new bucket elevator.

Materials, capacity, horsepower, and more

The first consideration in choosing a bucket elevator is the material to be conveyed. Sub-factors in material classification include size, flow capability, and abrasiveness. For example, crushed limestone has a density of 85 to 90 pounds per cubic foot and a capacity of 60 tonnage per hour. For limestone, Continental typically recommends its model COC elevator, which designates a continuous-style bucket mounted on a chain. For the proper size, one must determine the capacity in cubic feet per hour; for limestone, the result is 1,412.

The next step in bucket elevator selection is to determine capacity. The COC 14724 device can handle up to 1,518 cubic feet per hour. Then the customer should verify the allowable lump size for the continuous bucket. In the case of the COC 14724, the bucket measures 14 by seven inches – acceptable for limestone applications.

Next, the shaft centres of the elevator must be determined. Then the customer should determine horsepower and multiply the shaft centres by the horsepower-per-foot figure, then add the terminal horsepower to it. In the case of the Continental COC 14724, the equation works out to 50 times 0.102 plus 0.21, resulting in 5.31. This calculation is based on a material of 100 pounds per cubic foot, so it should be adjusted for a material of 85-90 pounds per cubic foot. The final result: 4.8 horsepower.

The final step in bucket elevator selection: further correct the total calculated horsepower for power-transmission loss. Drive efficiently is typically 85 per cent, so in the case of the COC 14724, the minimum required operating horsepower is 5.6. Apply a 7½-horsepower motor for smooth operation.

To learn more, contact Continental.

Share

Posted by Continental Conveyor Ltd

Continental Conveyor, established in 1963, specializes in the design, engineering, and manufacturing of mechanical bulk... Read more