The six key digital-production trends to which HARTING technology contributes

The six key digital-production trends to which HARTING technology contributes

May 23, 2018 REDWIRE is news you can use from leading suppliers. Powered by FRASERS.

Posted by Harting Canada Inc

The family-owned HARTING Group is a global leader in connectivity solutions. HARTING invented the modular connector and... Read more

Subscribe

Free REDWIRE e-newsletter

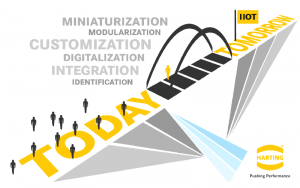

HARTING products and solutions contribute to six technological trends.

The HARTING Technology Group appeared at the Electronics Distribution Show in Las Vegas this month, and Jon DeSouza, president and CEO for North America, outlined its strategy in developing cyber-physical control infrastructure for advanced manufacturing. DeSouza identified six trends on which the company is focusing in creating digital production solutions.

Because innovation has always been a key part of HARTING’s success, it prioritizes realizing the full potential of the Industrial Internet of Things (IIoT). The company focuses on integrated products that use power and signal transmission, as well as gathering, distilling, and analyzing information at the Edge and in the Cloud.

Six areas of contribution

HARTING’s digital production solutions contribute to the following six trends:

- Miniaturization. HARTING’s award-winning ix Industrial connector series requires 70 per cent less installation space than the legacy RJ45, enabling it to deliver high performance while leaving a small footprint.

- Modularization. Since 1994, the Han-Modular connector series combines multiple connection types into a single interface, which saves space and allows extra flexibility. These modular connectors have experienced a 23 per cent increase in sales over the past six months, during a campaign emphasizing the modularization trend.

- Identification. In 2006, HARTING developed an industrial RFID solution with tracking functionality that allows objects to store data about themselves throughout their full life cycles, data that are easy to retrieve. This solution remains reliable even in harsh work environments.

- Integration. The MICA computing system is a perfect choice as a communications hub in any decentralized IIoT production environment. It can monitor energy in factory applications, including amount of power used, power quality, machine health, and process quality.

- Customization. HARTING’s Han-Eco thermoplastic connectors have customized hoods that make them compatible with data-centre tasks. Adapting them for industries’ individual needs makes them cost-efficient and effective.

- Digitalization. The MICA’s flexible configuration possibilities allow shop-floor and machine operations to be retrofitted for digital, networked applications. This results in efficient production, predictive maintenance, and better data documentation.

By adapting to these trends, HARTING digital production solutions remain strong and innovative.

To learn more, contact HARTING.

Share

Posted by Harting Canada Inc

The family-owned HARTING Group is a global leader in connectivity solutions. HARTING invented the modular connector and... Read more