The Rosta element: torsional spring innovation unleashes precision, power

The Rosta element: torsional spring innovation unleashes precision, power

December 1, 2023 REDWIRE is news you can use from leading suppliers. Powered by FRASERS.

Posted by Rosta Inc

Manufacturer: Since 1945 Rosta has been developing high quality standard and custom made dynamic machine-engineered rubb... Read more

Subscribe

Free REDWIRE e-newsletter

Equipment everywhere uses the Rosta element.

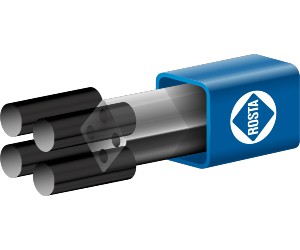

For nearly eight decades, businesses worldwide have counted on Rosta technology, including Canadian manufacturers working with Rosta Inc. The Rosta element, an elastomer-powered torsional spring, is central to the corporation’s range of specialized machine components, all constructed to provide a diverse blend of useful functions in one compact design. Rosta elements offer dependable performance across a broad variety of applications, encompassing three functions in one package – torsional spring, pivot bearing, and anti-vibration mount.

Operating angles of 30 degrees

The original technological concept developed by the Rosta team in 1944 is at the heart of every product, using an outer housing that contains an inner square surrounded by four rubber cords. This technology serves in countless tasks, with an operating angle of plus or minus 30 degrees and a range of torques and sizes. The rubber-suspension elements are designed mainly as torsional spring devices that offer operation angles of plus or minus 30 degrees as well. Pivoting the spring device generates more than torsional moments, depending on the particular function. According to the specific application, users typically must consider additional radial Fr, axial Fa, and/or cardanic Mk forces.

Rosta has been an ISO 9001-certified development, manufacturing, and distribution company for 31 years. All products undergo regular functional and quality testing. The team constantly tests and controls rubber inserts on the test machines of the in-house laboratory regarding Shore A hardness, compression set, abrasive wear, rebound resilience, tensile strength, breaking elongation, and aging behaviour.

The dimensional tolerances of the rubber inserts are defined as per the DIN 7715 standard, and the Shore A hardness is defined according to DIN 53505. The inner-core profiles and housings of the rubber-suspension elements are subject to the tolerance guidelines of the relevant production process and the respective supplier (cast, extruded, edge-rolled, etc.) and the individual material consistency (for example, aluminum casting, steel tube, or nodular cast iron parts).

The resulting torsional moments and spring deflections of Rosta rubber-suspension elements lie within a tolerance range of plus or minus 15 per cent at most, but usually fit within a narrower range.

To learn more, contact Rosta.

Share

Posted by Rosta Inc

Manufacturer: Since 1945 Rosta has been developing high quality standard and custom made dynamic machine-engineered rubb... Read more