The many benefits of piab’s new piFLOW®p SMART vacuum conveyor

The many benefits of piab’s new piFLOW®p SMART vacuum conveyor

August 27, 2019 REDWIRE is news you can use from leading suppliers. Powered by FRASERS.

Posted by Firing Industries Ltd

The business objective of FIRING INDUSTRIES LTD. is to consult with clients to select and supply technically complex PRO... Read more

Subscribe

Free REDWIRE e-newsletter

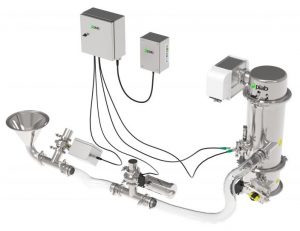

The piFLOW®p SMART conveyor by piab

piab manufactures processing equipment with innovative vacuum technology, available from Firing Industries. piab’s latest development, the piFLOW®p SMART conveyor, is nicknamed the Changeover Champion. This is a self-optimizing vacuum conveyor designed for companies that handle many different materials and/or those in which frequent changes are necessary. This saves substantial time and money in the food-processing and pharmaceutical sectors, with the device’s full changeover potential.

Changing material in ten minutes

With the vacuum technology of piab’s piFLOW®p SMART, manufacturers can change materials six times more quickly. This means that changes that take an hour in a conventional vacuum conveyor take ten minutes in this new device. The piFLOW®p SMART lives up to its name with every conveying cycle, configuring and optimizing a flawless flow of materials, set at the correct rate, to tune the process automatically.

A stand-alone system, the piFLOW®p SMART has machine learning software and sophisticated algorithms that run the application to reach the maximum capacity for conveyed material. The conveyor is equipped with calibrated level sensors for each conveyed material, and manual timer settings for starting/stopping the pump or opening/closing the bottom lid are not required. An air-carrying unit is integrated into the system to reach maximum material capacity. Using machine learning, the carrying air ratio is automatically set and continuously adjusted during the whole cycle. Because manual feed-adaptor tuning is no longer necessary, applications run at premium capacity. A pipeline-emptying unit is available to prevent blockage when there is a vertical lift higher than 25 feet.

Among the many benefits of this vacuum technology from Firing Industries:

- level sensors that guard against overfilling and monitor the emptying process;

- sensors cleaned by shock of air in each cycle, ensuring long life;

- storage of material settings to quicken the start process the next time material is conveyed;

- user-friendly touchscreen and self-adjusting settings;

- software, sensors, and air-carrying unit for operator-skill independence;

- anti-blockage function to ensure safe, smooth conveyance; and

- air-assisted sensor cleaning results in a system that needs minimal maintenance.

To learn more, contact Firing Industries’ application-sales engineers at ddubuc@firing.com or (877) 688-0974.

Share

Posted by Firing Industries Ltd

The business objective of FIRING INDUSTRIES LTD. is to consult with clients to select and supply technically complex PRO... Read more