The four things to consider when assembling Bergen cable systems

The four things to consider when assembling Bergen cable systems

November 10, 2021 REDWIRE is news you can use from leading suppliers. Powered by FRASERS.

Posted by Bergen Cable Technology, Inc

Mfr Mechanical Cable, Cable Assemblies & Push-Pull Controls. Original Mfr Of Safety Cable, A Patented Fastener Reten... Read more

Subscribe

Free REDWIRE e-newsletter

The Bergen website offers ample cable resources.

Bergen Cable is a team of cable experts that provides a wealth of valuable advice to customers, based on almost 80 years of company experience in the industry. The corporation’s website alone is an extensive source for expert resources and tips for clients about cable systems, ranging from basic information to wire-rope specifications. One section of the site deals with putting cable assemblies together, including the four most important considerations – assembly tolerances; conduit-length tolerances; safety factors in breaking strength; and the relationship between cable diameter and pulley or sheave diameter.

The standard safety factor

Manufacturing processes often rely on the overall length tolerances that cable systems need, plus the cable’s cut lengths. When putting cable assemblies together, this directly affects costs. Close assembly tolerances are usually more costly with respect to production and quality assurance. Clients should ask the Bergen crew to review and approve allowable tolerance and inspection techniques prior to production.

The distance between designated measuring points, as shown in the different sections when specifying assembly lengths, should be considered. Usually, these measuring points are located at the fittings’ load-bearing points. Commercial tolerance should equal plus or minus two per cent of the length for an assembly length of at least 100 feet, and special tolerance should be plus or minus one per cent of the length. As the lengths decrease, so do these tolerance figures.

Ahead of production, acceptable conduit-length tolerances and inspection methods should be reviewed by the Bergen team. Overall tolerance must be plus or minus ¼ of an inch for conduit lengths from one to two feet, or 0.062 of an inch for lengths shorter than one foot.

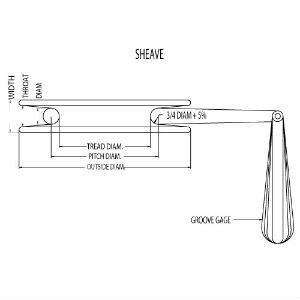

Another important factor to consider: direct stress and the shock in bending loads when finding the cable’s working load. The user should apply a reasonable breaking-strength safety factor to the load. In many cases, the standard safety factor is five to one. Last, pulleys that are properly designed can boost cable fatigue life, so the smallest possible ratios of the tread and cable diameters should be identified in cable systems.

To learn more, contact Bergen.

Share

Posted by Bergen Cable Technology, Inc

Mfr Mechanical Cable, Cable Assemblies & Push-Pull Controls. Original Mfr Of Safety Cable, A Patented Fastener Reten... Read more