The drive assemblies available from Continental for its screw conveyors

The drive assemblies available from Continental for its screw conveyors

March 2, 2020 REDWIRE is news you can use from leading suppliers. Powered by FRASERS.

Posted by Continental Conveyor Ltd

Continental Conveyor, established in 1963, specializes in the design, engineering, and manufacturing of mechanical bulk... Read more

Subscribe

Free REDWIRE e-newsletter

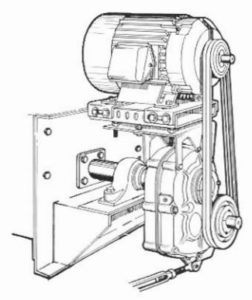

Continental offers shaft-mounted reducers among other drive assemblies for its screw conveyors.

Continental Conveyor manufactures and supplies high-end material-handling systems and related products for Canadian industry. This includes screw conveyors and their key accessories, like drive assemblies. The company offers numerous combinations and types of drives for these conveyor products, both the inclined and vertical models. The more frequently used drives and mechanical arrangements available include screw-conveyor drives, shaft-mounted reducers, gear-motor drives, and other varieties of drives and configurations to suit all user needs.

Electric motor contributes to versatility

A screw-conveyor drive is a type of drive assembly that consists of a modified shaft-mounted reducer complete with a V-belt drive and motor mount in an integral unit. This assembly blends the reducer output shaft, conveyor thrust bearing, end seal, and adaptor flange for mounting integrally to the trough end. The user can mount the electric motor in either the horizontal or the vertical plane, which adds to the versatility of these drive assemblies.

Shaft-mounted reducers are essentially very similar to screw-conveyor drives. Each of these units requires the use of a thrust bearing, drive shaft, and seal assembly. As with a screw-conveyor drive, the user can blend the motor mount integrally with the reducer unit and transmit power through a V-belt drive. Shaft-mounted reducers are typically used in applications that require special sealing arrangements on the conveyor shafts, like packed gland seals, or transmission of very high horsepower that is not within the parameters of the screw-conveyor drive.

Another type of drive assemblies available from Continental is gear-motor drives. These are used to power conveyors through either direct, low-speed couplings mounted to the conveyor drive shafts or through roller-chain drives. The former are typically mounted on scoop bases attached to the trough ends, and the latter are mounted directly on top of conveyors or on adaptor bases or base plates beside the conveyors. These units are common when high horsepower is being transmitted or variable-speed gear motors are used to change metering screws’ feed rates.

Numerous other methods of driving screw conveyors are available, including variable-speed DC motors with SCR rectifiers, hydraulic drives, and variable pitch sheaves.

To learn more, contact Continental.

Share

Posted by Continental Conveyor Ltd

Continental Conveyor, established in 1963, specializes in the design, engineering, and manufacturing of mechanical bulk... Read more