The components that make Continental heavy-duty apron feeders run smoothly

The components that make Continental heavy-duty apron feeders run smoothly

June 8, 2020 REDWIRE is news you can use from leading suppliers. Powered by FRASERS.

Posted by Continental Conveyor Ltd

Continental Conveyor, established in 1963, specializes in the design, engineering, and manufacturing of mechanical bulk... Read more

Subscribe

Free REDWIRE e-newsletter

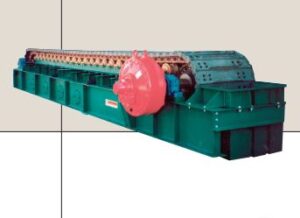

Continental makes and supplies apron feeders.

Continental Conveyor Ltd. manufactures and supplies a broad variety of material-handling systems – more than just standard conveyors. The company also provides heavy-duty apron feeders. Designed and built for challenging work conditions, these are rugged pieces of equipment intended for feeding and moving heavy, lumpy, or abrasive material in harsh environments.

With a robust design, apron feeders are constructed from a wide range of components that ensure challenging applications at all times.

Chains, rollers, sprockets, and more

Heavy-duty apron feeders by Continental consist of three main features:

- Chains and rollers. Crawler tractor chains have a rugged design that makes them ideal for the severe environments in which apron feeders operate. Their various standard pitches and tensile strength ratings enable a suitable selection for all application widths and lengths. Carrying and return rollers have hardened wheels and pins for long wear life, with a large lubricant reservoir that is factory-sealed for life.

- Sprockets and traction wheels. A standard feature, these wheels have segmental runs that are machined and jig-drilled to fit on the mounting hubs keyed to the shafts. Users can easily remove sprocket segments for replacement, and the segments are reversible for double life.

- Cast manganese or fabricated pans. A work-hardening steel alloy, cast manganese is perfect for high-impact and abrasive applications. Impact ribs cast into the pan longitudinally and blended with the impact rail on the feeder structure decrease material leaks between pans. Raised pads offer a smooth mounting surface for the chain when cast laterally into the pans. For most average conveying and feeding tasks that do not involve high impact or abrasion, Continental recommends double-beaded overlapping formed steel pans, fabricated from mild steel or abrasion-resistant plate. They are also suitable for applications with a moderate amount of impact when they are combined with an impact rail to limit deflection.

In addition to these main features, Continental apron feeders run with a broad variety of mechanical and structural components. Examples include drive sprockets, pillow block bearings, and feeder drives on the mechanical side, and inlet chutes and cross members for structure.

For more information, contact Continental.

Share

Posted by Continental Conveyor Ltd

Continental Conveyor, established in 1963, specializes in the design, engineering, and manufacturing of mechanical bulk... Read more