The basics about the professional broaching techniques at Ohio Broach

The basics about the professional broaching techniques at Ohio Broach

December 1, 2021 REDWIRE is news you can use from leading suppliers. Powered by FRASERS.

Posted by The Ohio Broach & Machine Co.

If you’re looking for accuracy, efficiency, flexibility, and economy in the production of metal parts, broaching i... Read more

Subscribe

Free REDWIRE e-newsletter

Ohio Broach employs true broaching experts.

The Ohio Broach & Machine Company has been a leader in virtually every type of professional broaching service that a client could need for 65 years now. But what is broaching? This is a question that deserves a lengthy, detailed answer to express the full scope of the service range that this company offers. A valued and important machining technique, broaching offers a unique level of efficiency and precision overall.

Recommended for unusual metal shapes

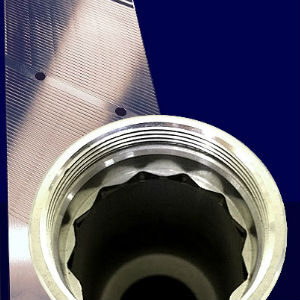

A process for removing material from metal, typically less than Rc 30 in hardness, broaching is usually done with a toothed tool called a broach. Similar to a saw, this tool has teeth that increase in height over its length, which builds “feed” into the broach. Each of the different sections works for a different broaching technique – like roughing, semi-finishing, or finishing – by varying the teeth’s height differences.

Often used in precision machining, professional broaching is especially recommended for unusual metal shapes. Common examples of broached surfaces: serrations; splines; keyways; and flat surfaces. Frequently processed work pieces include castings, forgings, screw-machine parts, and stampings.

Two main types of broaching, internal and external broaching, are available from Ohio Broach. Internal broaching involves running the broach linearly through a pilot hole in the piece to make a cut in a pull- or push-type broaching machine, while external broaching is the technique of running a broach linearly against the piece’s surface to effect a cut, usually in a vertical surface broaching machine. Each method usually requires only one pass to make the cut, and both yield results with more precision and higher speed than most other machining processes do.

Ohio Broach offers virtually any specific professional broaching service that exists, and it makes and sells broaching machines for private users to do their own broaching jobs. And this is not all: the company also provides sharpening, repair, and reconditioning services to keep machines and tools in top condition. Through production broaching, the Ohio Broach crew employs its strong skills and longtime experience to machine a broad variety of shapes and parts.

For more information, contact Ohio Broach.

Share

Posted by The Ohio Broach & Machine Co.

If you’re looking for accuracy, efficiency, flexibility, and economy in the production of metal parts, broaching i... Read more