The basic structure and fit types of Tsubaki engineering chains

The basic structure and fit types of Tsubaki engineering chains

March 25, 2020 REDWIRE is news you can use from leading suppliers. Powered by FRASERS.

Posted by Tsubaki Of Canada Ltd.

Since 1973, the Canadian market has trusted Tsubaki of Canada Limited, a division of Japan’s Tsubakimoto Chain Co.... Read more

Subscribe

Free REDWIRE e-newsletter

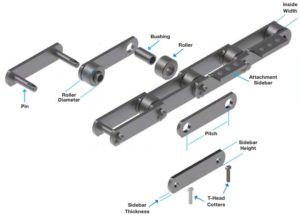

Tsubaki engineering chains consist of several parts.

Tsubaki of Canadaʼs portfolio of chain products includes engineering chains. These are specially constructed and tested by the Tsubaki team to outlast other chains and make applications more cost-efficient. They are perfect for sanitary environments, extreme temperatures, freezers, or exposure to corrosive chemicals, the outdoors, or excessive moisture.

Each of these chains has three fundamental dimensions: pitch, roller diameter, and inside link width. The chain is compatible with the sprockets when these dimensions are equal.

Press fit or slip fit

Engineering chains come with two kinds of construction: press fit or slip fit. Press fit, the more common type, puts the pins and sidebars together with a tight forced fit, to keep the pins and bushing rotating about fixed points and increase the chainʼs fatigue life. Slip-fit chains have a loose fit between pins and sidebars, which makes assembly easier.

The following elements make up Tsubaki engineering chains:

- Pin. The pin connects the inside link to the outside one and transmits chain tension along the direction of travel, while receiving vertical reaction forces from the conveyed items. This is an essential strength-bearing component that requires high wear resistance.

- Bushing. Another strength-bearing component, which receives tension forces during sprocket engagement. But its main purpose is to serve as a bearing component. The outside diameter is subject to wear from sliding against the rollerʼs inner diameter during roller rotation, and the inner diameter is subject to wear from sliding against the pinʼs outer diameter as the chain articulates.

- Roller. This forms a slip fit with the bushing, and its rotation lowers sprocket tooth wear when engaging with the sprocket. Roller rotation also alleviates the shock and wear from the teeth, while reducing chain-pull resistance.

- Sidebar. Receives the tensile load along the direction of travel and vertical reactive forces when supporting items.

- Attachment sidebar. Some sidebars are designed to accommodate attachments of slats, aprons, fixtures, and more.

- T-head cotter. Inserted and bent to ensure that the pin remains fully engaged with the sidebar, after the outer plate is press-fit to the pin.

To learn more, contact Tsubaki.

Share

Posted by Tsubaki Of Canada Ltd.

Since 1973, the Canadian market has trusted Tsubaki of Canada Limited, a division of Japan’s Tsubakimoto Chain Co.... Read more