Strain gauges provide high resistance to alternating loads

Strain gauges provide high resistance to alternating loads

July 6, 2017 REDWIRE is news you can use from leading suppliers. Powered by FRASERS.

Posted by Durham Instruments

One Source For All Your Quantitative Measuring Needs. With Over 50 Yrs.Of Experience In The Instrumentation Field. It Of... Read more

Subscribe

Free REDWIRE e-newsletter

When strain gauges are subject to alternating loads at increased load levels, they can weaken and fail early. M Series foil strain gauges, manufactured by ADE Technologies and available in Canada through Durham Instruments, are specially designed to resist alternating loads at increased strain levels and high temperatures up to 300 degrees C (572 degrees F).

The lineup

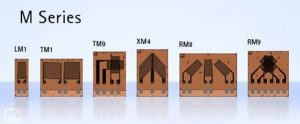

M Series foil strain gauges feature measuring grids made of a special nickel-chromium alloy. They are available with various geometries, measuring grid lengths, and temperature response matching. The selection includes:

- LM1: A linear strain gauge with one measuring grid for strain measurements in one direction.

- TM1: A T rosette with two measuring grids arranged at a 90-degree angle to each other. This model is ideal for measuring tensile and compressive stress.

- TM9: A stacked T rosette with two measuring grids arranged at 90-degree angles to each other. Like the TM1 model, it is best suited for measuring tensile and compressive stress.

- XM4: A V-shaped strain gauge with two measuring grids arranged at an angle of ±45 degrees. This model is ideal for determining torsion and shear stress.

- RM8: A rectangular rosette with three measuring grids arranged at angles of zero, 45 and 90 degrees.

- RM9: A stacked rosette with three measuring grids arranged at angles of zero, 45 and 90 degrees.

Grid length options

These strain gauge types are available in various lengths — 1.5, three and six millimetres. Users should select 1.5-millimetre lengths in applications where space is a constraint or when highly selective measurement results are required. Three-millimetre lengths are most appropriate for inhomogeneous materials like concrete or wood, while six-millimetre models are ideal for inhomogeneous materials where space is not a requirement. In general, measuring grid lengths of three to six millimetres generate a better result.

For additional details, contact Durham Instruments.

Share

Posted by Durham Instruments

One Source For All Your Quantitative Measuring Needs. With Over 50 Yrs.Of Experience In The Instrumentation Field. It Of... Read more