Sidener hydraulic valves heighten both precision control and safety

Sidener hydraulic valves heighten both precision control and safety

June 28, 2019 REDWIRE is news you can use from leading suppliers. Powered by FRASERS.

Posted by Wainbee Limited

Market demands for specialized services have allowed Wainbee Limited to enhance our offerings from its original industri... Read more

Subscribe

Free REDWIRE e-newsletter

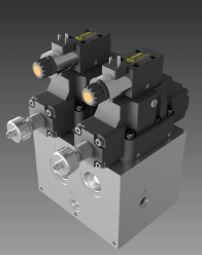

Wainbee offers hydraulic safety valves by Sidener.

Precision control is one of the major benefits of many industrial products from Wainbee Limited. The supplier carries ample equipment for this purpose, including Sidener Engineering’s control-reliable hydraulic safety valves. These units are recommended for applications in which hydraulic safety is a concern, such as hydraulic presses, coil slitting lines, paper processing and roll handling, rubber molding, actuator isolation, and metal-forming tasks like cutting, bending, or punching.

Redundancy and fault detection

Sidener has designed two types of hydraulic safety valves for maintaining control reliability. This refers to designing, constructing, and installing a safety system so that the failure of any component in the device or system does not prevent the machine’s proper stopping action from occurring; it prevents initiation of a successive machine cycle until the failure is corrected. Reliability and fault detection are the key features of a device that achieves this successfully.

To cover all safety-application needs, Wainbee offers two types of Sidener control-reliable hydraulic safety valves:

- Blocking valves. Each of these units functions as a two-position, two-way hydraulic valve with redundant valving elements and redundant monitoring. These valves are designed specifically to block flow in a hydraulic system. Frequently used for blocking flow in hydraulic cylinders to inhibit cylinder movement caused by gravity.

- Energy-isolation valves. These valves work as two-position, three-way hydraulic valves, also with redundant valving elements and monitoring. When energized, these valves each provide a path for a flow of hydraulic liquid from its source to the hydraulic system. The valve also blocks flow from the hydraulic energy source and vents the hydraulic system to tank when it is de-energized. The hydraulic circuitry has a series flow condition from the valve inlet through redundant valving elements to the valve discharge. Another feature is a parallel flow condition from the discharge through either or both of the valving elements to the tank port. If an element fails to operate as required, inlet flow is blocked and liquid from the outlet side is directed to tank.

Sidener’s control-reliable hydraulic safety valves are suitable for ISO-13849 PLd and ISO-1389 PLe applications.

For more information, contact Wainbee.

Share

Posted by Wainbee Limited

Market demands for specialized services have allowed Wainbee Limited to enhance our offerings from its original industri... Read more