Safety swivel hoist rings among Ken Forging’s offerings

Safety swivel hoist rings among Ken Forging’s offerings

May 28, 2015 REDWIRE is news you can use from leading suppliers. Powered by FRASERS.

Posted by Ken Forging

Drop Forged Industrial Hardware, Eyebolts, Nut Eyebolts, Rod Ends, Turnbuckles And Fittings, Eye Nuts, Clamps Wedges, Pa... Read more

Subscribe

Free REDWIRE e-newsletter

Ken Forging started in a 20' x 20' garage 45 years ago and has grown into a leading manufacturer in the forging business. Though originally strictly an eyebolt manufacturer, the Jefferson, Ohio-based company has expanded its capabilities and product selection to provide one of the broadest selections of forged hardware available today.

Among its lineup of offerings are swivel hoist rings, available in metric, longbar and standard U-Bar types, in capacities up to 50,000 pounds. The company’s safety swivel hoist rings are made with AISI 4140 steel alloy and have a black oxide finish. In addition, Ken Forging thoroughly checks its hoist rings to ensure they are always free of defects. In fact, its products undergo 100 per cent magnetic particle inspection, and all other load bearing parts are inspected to ASTM E709-08 & MIL-STD-105 standards with zero permissible defects. In addition, it performs 200 per cent proof-load testing on all of its hoist rings.

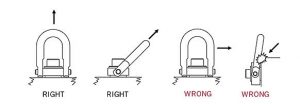

It’s no surprise, then, that safety is very important at Ken Forging — so important that the company outlines safety precautions for its safety swivel hoist rings on its website. It recommends regular inspection for wear and strict adherence to user instructions to prevent failure. Other tips include:

- Regardless of the 5:1 safety factor, never exceed the rated capacity on hoist rings. This safety margin is needed in case of misuse, which could drastically lower load capacity.

- Make sure the hoist ring pivots and rotates in all directions freely.

- Tighten mounting screws to torque recommended. Periodically check torque because screws could loosen in extended service.

- Do not apply shock loads. Always lift gradually. Repeat magnaflux testing if shock loading ever occurs.

- Tensile strength of parent material should be above 80,000 PSI to achieve full load rating. For weaker material, consider through-hole mounting with a nut and washer on the other side.

Ken Forging will be exhibiting at Fastener Tech ‘15 from June 8-10 at the Donald E. Stephens Convention Center in Rosemont, Ill. Visit the company at booth 1019/1120, and learn more about its products and capabilities. Contact Ken Forging at sales@kenforging.com for more details about attending Fastener Tech '15.

Share

Posted by Ken Forging

Drop Forged Industrial Hardware, Eyebolts, Nut Eyebolts, Rod Ends, Turnbuckles And Fittings, Eye Nuts, Clamps Wedges, Pa... Read more