Red-D-Arc offers its top expert tips on welding stainless steel

Red-D-Arc offers its top expert tips on welding stainless steel

January 18, 2019 REDWIRE is news you can use from leading suppliers. Powered by FRASERS.

Posted by Red-D-Arc Welderentals

Offers A Full Range Of Rental Welding And Positioning Equipment For A Variety Of Processes And Applications... Read more

Subscribe

Free REDWIRE e-newsletter

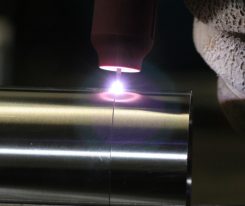

Red-D-Arc has ample equipment -- and advice -- for welding stainless steel.

Red-D-Arc Welderentals supplies a wide range of rental equipment for welding stainless steel. As experts in welding, the Red-D-Arc team has plenty to offer in advice for customers looking to get the most out of its products. Since stainless steel has properties that differ from mild steel, users must consider the effect on welding.

A recent blog post by Red-D-Arc, summarized below, offers the company’s main tips on welding stainless steel.

The two most common processes

Stainless steel contains at least 10.5 per cent chromium, which resists corrosion when it forms an oxide layer on the surface. Most types of stainless steel have good weldability characteristics, and the two most common processes are TIG (GTAW) and MIG (GMAW), although stick welding also works.

Welders need to consider three stainless-steel traits before embarking on the task:

- High coefficient of expansion, which causes more distortion;

- Low coefficient of heat transfer, requiring lower heat input as the steel is conducted away slowly; and

- Low electric conductivity, meaning that the correct, consistent stick-out distance is vital for MIG/TIG welding.

Red-D-Arc recommends welding stainless steel in a work area segregated from carbon steels and not using the same tools for welding both. This safeguards carbon steels from contamination, which may lead to welding defects and rust on stainless steel. Before starting the task, welders must clean joint surfaces and filler wire thoroughly to remove all dirt, grease, or oil. In addition, the joint design must cater to stainless steel’s higher expansion rate.

Filler materials are typically the same as the base metal, so workers must take special considerations in choosing filler if welding different types of stainless steel. Filler is selected to lower the risk of intergranular corrosion and hot cracking.

Other important considerations: protect the weld with a mainly inert gas; apply accurate preheat to martensitic steel and maintain a minimum interpass temperature to prevent cracking; restrict the heat input below 148 degrees Celsius for ferritic and duplex steels; and remember to clean and passivate stainless steel welds afterwards, to ensure corrosion resistance and good appearance.

For more information, contact Red-D-Arc.

Share

Posted by Red-D-Arc Welderentals

Offers A Full Range Of Rental Welding And Positioning Equipment For A Variety Of Processes And Applications... Read more