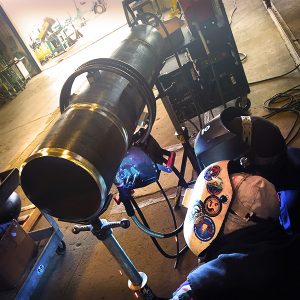

Red-D-Arc has the equipment to weld small and large pipes

Red-D-Arc has the equipment to weld small and large pipes

January 4, 2019 REDWIRE is news you can use from leading suppliers. Powered by FRASERS.

Posted by Red-D-Arc Welderentals

Offers A Full Range Of Rental Welding And Positioning Equipment For A Variety Of Processes And Applications... Read more

Subscribe

Free REDWIRE e-newsletter

Red-D-Arc rents out a broad portfolio of welding equipment for different pipe applications.

Red-D-Arc Welderentals not only supplies the top equipment on the market for industrial pipe welding; it also employs a team of experts who can advise on the right process for the welding application. This is important, as the proper method for pipe always depends on the location of the task, the materials, and pipe size.

Here is the company’s expert input on the right methods to choose for different welding applications.

Three different pipe types

For welding steel pipes in the open – pipe installation in trenches, for example – the company recommends manual arc welding (SMAW), using welding units optimized for downhill welding. Workers use this technique downhill with cellulosic electrodes, and also basic electrodes for higher-strength steel applications). After a root pass and hot pass, fill passes are required, followed by the top pass.

For pipes with small diameters and short lengths, and that are free to rotate, the welder rotates the pipe while holding the welding torch stationary. The proper processes in this case are MIG (GMAW) and TIG (GTAW), the latter requiring a wire feeder. Red-D-Arc recommends using a process cell too.

In the case of larger pipe sizes, the orbital process of pipe welding is the typical method. Although MIG is most common here, TIG with automatic feed of the filler wire will also do. The orbital process with closed-head welding units is also recommended for smaller pipe that cannot be rotated.

Advanced methods of depositing pipe welds include precisely controlled short-circuit transfer for root pass, optimized pulsed welding, and high-frequency waveform control. The latter is recommended for speeding up and improving the quality of the pipe welds.

For any of these applications, Red-D-Arc can supply a wide variety of welding equipment for rental. Examples include: closed-head orbital welding units, for small pipe diameters; orbital TIG systems, built for larger diameters; orbital MIG welding systems; process pipe cells with oscillating open-arc welding; TIG and MIG welding power sources suitable for above; and cutting and bevelling saws for pipe diameters of up to 325 millimetres.

Trust Red-D-Arc for all the top welding solutions.

For more information, contact Red-D-Arc.

Share

Posted by Red-D-Arc Welderentals

Offers A Full Range Of Rental Welding And Positioning Equipment For A Variety Of Processes And Applications... Read more