Rapid Gear serves demanding industries with ease

Rapid Gear serves demanding industries with ease

September 15, 2017 REDWIRE is news you can use from leading suppliers. Powered by FRASERS.

Posted by Rapid Gear

Rapid Gear has been at the forefront of building and designing individual gears, gear boxes, and special purpose machine... Read more

Subscribe

Free REDWIRE e-newsletter

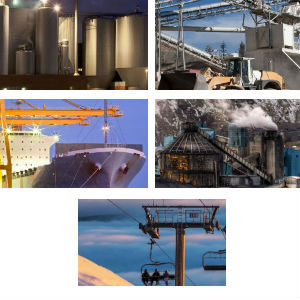

When it comes to building and designing individual gears, gearboxes and special purpose machinery, Rapid Gear is an industry leader, and has been for more than 40 years. The Kitchener, Ont.-based company has a full-service machining department to support its gear-cutting operations, as well as a team of experienced craftsmen to design and build new gears and gearboxes, and restore and redesign old gears and gearboxes. Over the last four decades, a range of critical industries have benefited from this expertise, and have come to rely on Rapid Gear for its high-quality service and products.

Military

Rapid Gear manufactures specialized gearing for military applications. The company, which is Controlled Goods Certified (CGC), has expertise in the rebuilding, maintenance and replacement of gearboxes for the military and navy, as well as the repair and replacement of leaking seals, gearboxes, and input cartridge bearings and seals.

Mining and aggregate

Use of high-quality gears and gearboxes, and regular maintenance to ensure optimal performance, are critical in the demanding mining and aggregate sectors. Rapid Gear has the capability to replace leaking seals, repair or replace gearboxes, and replace input cartridge bearings and seals.

Cranes and lifting equipment

Heavy lifting and constant speed changes create high stress and uneven wear on gearboxes, while high temperatures break down lubricants and seals, reducing bearing life. The high-quality materials used by Rapid Gear to manufacture its products can handle these demands. The company also has the expertise to maintain, repair or replace gears and gearboxes impacted by challenges.

Pulp and paper

The pulp and paper sector is a wet environment with high humidity, which is known to corrode metals and contaminate lubricants. Equipment is also exposed to high ambient temperatures, which breaks down lubricants and seals, and reduces bearing life. It is important to use equipment and components that can reliably operate in these environments, and regularly maintain these items to ensure they’re always working to the best of their abilities. Rapid Gear can replace leaking seals and input cartridge bearings, and repair or replace gearboxes in this sector.

Ski lift repairs

Ski-lift and gondola operators call Rapid Gear when they have leaking seals that need to be replaced, and when they require bull wheel machining or replacement, and input cartridge bearing and seal replacement. The company offers a quick and cost-effective service to provide peace of mind to operators.

Additional details

Rapid Gear also offers onsite inspection of customer gears for added convenience in all of these sectors. For more information, contact Rapid Gear.

Share

Posted by Rapid Gear

Rapid Gear has been at the forefront of building and designing individual gears, gear boxes, and special purpose machine... Read more