Process Heaters offers Dynisco fluidized baths for cleaning dirty tools

Process Heaters offers Dynisco fluidized baths for cleaning dirty tools

February 6, 2019 REDWIRE is news you can use from leading suppliers. Powered by FRASERS.

Posted by Process Heaters Inc

We specialize in process heating equipment, electronic temperature controls, and temperature and pressure sensors for ev... Read more

Subscribe

Free REDWIRE e-newsletter

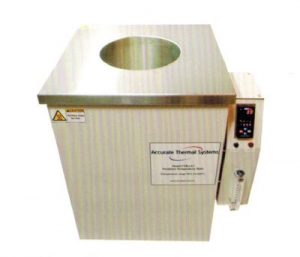

PolyClean fluidized baths provide a convenient and efficient way to clean metal parts.

Process Heaters is highly respected as a source of heating products from quality manufacturers, including Dynisco. Their offerings include Dynisco’s PolyClean fluidized baths, one of the company’s polymer evaluation ancillary products. These baths provide a convenient and efficient way to clean dirty parts and tooling.

PolyClean fluidized baths usually offer quicker processing times than ovens and furnaces do, and they are also much more thermally stable and uniform.

A simple three-step process

Fluidized baths are open-top vessels that are filled with ultra-pure aluminum sand. The device operates by fluidizing the sand when a controlled airflow percolates up through the sand bath, so that the sand is effectively floating on an air cushion. The user can adjust the temperature of the bath, up to nearly 600 degrees Celsius as required.

Cleaning parts in these baths is a simple three-step process. First, the user selects the parts to be processed – typically encrusted with hardened plastics, paint, oil, rubber, adhesives, or epoxy. Second, these parts are placed into a parts basket. The third step is to lower the basket into the heated bath and leave them for 30 to 60 minutes. It is as simple as making toast. Drop in the parts and go have a coffee. When you come back, the parts will be clean.

Using these baths from Process Heaters is an ideal alternative to the typical process of heating parts with a torch and scraping them clean – a method that not only is tedious and time-consuming, but may alter the parts’ metallurgy. Benefits and features of PolyClean baths include the following:

- Automatically controlled fluidizing air, making flow monitoring unnecessary;

- Uniform temperature throughout the bath;

- Independent over-temp protection; and

- Optional air-filtration system to remove fumes and odours from exhaust stream.

Dynisco’s PolyClean fluidized baths are recommended by tool and die manufacturers everywhere, for their high labour efficiency and fast return on investment. They are safer to operate than molten salt baths are, making immersed parts clean and dry with no material left to remove. This is the right way to prevent tool damage.

To learn more, contact Process Heaters.

Share

Posted by Process Heaters Inc

We specialize in process heating equipment, electronic temperature controls, and temperature and pressure sensors for ev... Read more