Ohio Broach offers tool sharpening and reconditioning among its services

Ohio Broach offers tool sharpening and reconditioning among its services

July 6, 2021 REDWIRE is news you can use from leading suppliers. Powered by FRASERS.

Posted by The Ohio Broach & Machine Co.

If you’re looking for accuracy, efficiency, flexibility, and economy in the production of metal parts, broaching i... Read more

Subscribe

Free REDWIRE e-newsletter

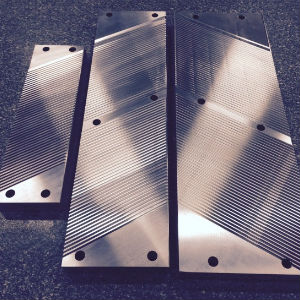

Tool sharpening is a major service at Ohio Broach.

As a major broaching provider since the 1950s, The Ohio Broach and Machine Company offers top services in this field. Not only this: the company produces broaching machines and the ideal tool for any application. Yet another popular service available from Ohio Broach is broaching-tool sharpening and reconditioning. With the Ohio Broach team’s tool-sharpening capabilities, clients always know that their broaching tools will function at their peak.

Broad range of tools

The Ohio Broach crew manufactures a variety of broaching tools at its Willoughby, OH facility, with various capabilities like different sizes of broach inserts, magazine well pull broaches, spline pull broaches, bearing cage rectangular pull broaches, and serrated tooth form broach inserts. The company encourages potential clients to get in touch for free project quotes, with info on the forms that need to be broached.

Making custom-designed broaching tools results from a collaborative effort between the customer and the talented Ohio Broach engineering team. The company uses this close collaboration to determine the correct length, pitch, tooth load, face angle, and clearance angles to comply with the customer’s individual requirements.

Ohio Broach also provides precision sharpening, reconditioning, and repair of broach tools, in addition to brazing, straightening, and re-coating. Proper broaching-tool sharpening is vital to maintain accurate cuts and machine quality products. The staff can use sharpening and reconditioning to improve round broaches, key ways, surface broaches, and form broaches made from high-speed steel easily. Precision machining of broaching tools is also available, as per any specifications with in-house CNC regrinding equipment and radius and face-angle gauging set.

Another key advantage of working with Ohio Broach is its unique 24-hour emergency sharpening service for customers with urgent requirements. The usual waiting time for sharpening projects is a week or two, depending on the amount of tools. Ohio Broach extends tool life with coatings like titanium nitride, titanium carbonitride, or titanium aluminum nitride.

For a better look at Ohio Broach’s sharpening abilities for broaching tools, check out this video:

To learn more, contact Ohio Broach.

Share

Posted by The Ohio Broach & Machine Co.

If you’re looking for accuracy, efficiency, flexibility, and economy in the production of metal parts, broaching i... Read more