Ohio Broach keeps broaching operations smooth with sharpening, repair services

Ohio Broach keeps broaching operations smooth with sharpening, repair services

August 24, 2018 REDWIRE is news you can use from leading suppliers. Powered by FRASERS.

Posted by The Ohio Broach & Machine Co.

If you’re looking for accuracy, efficiency, flexibility, and economy in the production of metal parts, broaching i... Read more

Subscribe

Free REDWIRE e-newsletter

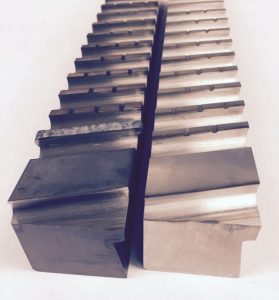

Tool sharpening, as well as machine reconditioning and repair, are among Ohio Broach's services.

Broaching machines and tools are important to many manufacturing processes, and products from the Ohio Broach & Machine Company offer precision results for high-quality production runs. But a company gets optimal results only when the machines and tools work properly. This is why Ohio Broach offers broach tool sharpening, along with machine reconditioning and repair.

Clients continue to rely on Ohio Broach’s sharpening, reconditioning, and repair services to keep their operations running smoothly.

A variety of equipment

To keep the edges on broaching tools keen, Ohio Broach has access to a variety of equipment for its broach tool sharpening services. This equipment ranges from round sharpeners to flat sharpening machines, including CNC-controlled machines. These precision machines have specially coated, hard wheels specifically designed to grind the hard materials that today’s broach tools are manufactured from. Flood coolant is another asset that helps Ohio Broach to provide broach tool sharpening of the highest quality. And the company’s Radius and Face Angle Checking gauge sets for checking tooth profiles and forms are also available for clients who do their own sharpening.

For manufacturers throughout North America that use their own broaching machines, Ohio Broach offers convenient machine rebuilding and repair services. With its experience in designing and building new machines, the Ohio Broach team can take any out-of-service machine and make it productive and efficient again. Staff members clean, grind, and replace worn individual parts, such as ram slides, gibs or wear plates, after taking machines apart. The company’s horizontal and vertical CNC milling centres and grinding machines enable fabrication of all required components.

Each machine typically takes four to five months to rebuild, with up-to-date hydraulic and electrical systems as required. Ohio Broach can also retrofit older machines to accommodate more recent automated technology. The company will inspect the installation and offer start up services at the client’s workplace.

An ISO 9001-certified company, Ohio Broach always promises quality in its sharpening, repair, and reconditioning services. These capabilities are useful for customers in many industries, including agriculture, the automotive sector, the military, trucking, aerospace, hand tools, oil and gas, and the medical field.

To learn more, contact Ohio Broach.

Share

Posted by The Ohio Broach & Machine Co.

If you’re looking for accuracy, efficiency, flexibility, and economy in the production of metal parts, broaching i... Read more