Ohio Broach has the expertise and equipment to perform quality tool sharpening services

Ohio Broach has the expertise and equipment to perform quality tool sharpening services

April 5, 2016 REDWIRE is news you can use from leading suppliers. Powered by FRASERS.

Posted by The Ohio Broach & Machine Co.

If you’re looking for accuracy, efficiency, flexibility, and economy in the production of metal parts, broaching i... Read more

Subscribe

Free REDWIRE e-newsletter

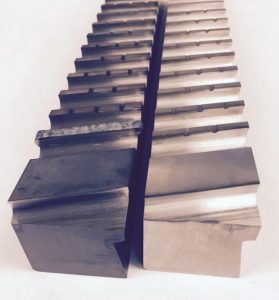

Known as the “total broaching source”, the Ohio Broach & Machine Company offers services in all aspects of broaching, from the design and manufacturing of machines to production broaching services. Tool sharpening is an important part of the company’s offering because properly sharpened tooling is an essential part of the broaching process. In fact, a properly sharpened tool can reduce downtime and assure high-quality results.

To keep customers’ broaching operations running smoothly, the Ohio Broach & Machine Company has the equipment and expertise to provide precision tool sharpening.

Tool sharpening capabilities

To perform broach tool sharpening services, the Ohio Broach & Machine Company is outfitted with top quality sharpening equipment. This includes all types of machines, from grinding wheels to round sharpeners and flat sharpening machines with CNC control.

The grinding wheels Ohio Broach uses are specially coated and specifically designed for grinding the hard materials that broach tools are made from. The company can also provide coating services to extend the life of broach tools. Some of the coatings available include titanium nitride, titanium carbon nitride and titanium aluminum nitride.

Using this high precision equipment, the company is known for providing tool sharpening of top quality. The Ohio Broach & Machine Company verifies the accuracy of its work using radius and face angle checking gauge sets. These gauges are used to check the broach tool’s tooth profile and form. The company can also supply these gauge sets for customers who perform their own tool sharpening.

More information

Another service offered is that Ohio Broach has the capability to receive a customer's holder bar and broach assembly, and remove the broaches for sharpening. After sharpening is completed, the tool is reset into the broach holder bar to blueprint dimensions, so the customer receives an assembly that is ready to install in their broaching machine. The company's sharpening services have a 24-hour turnaround, if needed, to help customers with emergencies.

Share

Posted by The Ohio Broach & Machine Co.

If you’re looking for accuracy, efficiency, flexibility, and economy in the production of metal parts, broaching i... Read more