Norpak’s advice on picking the right parcel or package conveyor

Norpak’s advice on picking the right parcel or package conveyor

June 1, 2021 REDWIRE is news you can use from leading suppliers. Powered by FRASERS.

Posted by Norpak Handling Limited

Norpak Handling provides conveying products and complete turn-key systems to suit your requirements and solve your probl... Read more

Subscribe

Free REDWIRE e-newsletter

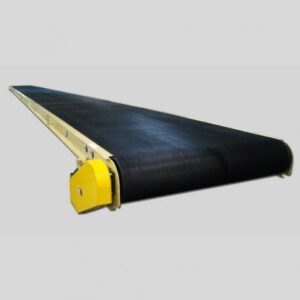

Parcel/package conveyors are ideal for e-commerce.

With the growth of e-commerce in recent years, many businesses seek innovative methods of conveying and sorting parcels for shipment. A parcel or package conveyor is an appropriate solution. Norpak Handling Ltd. offers several great options for this application – and knows there is more to such systems than conveyors.

A recent blog entry by Norpak offers valuable tips to plants and warehouses on getting the most out of package/parcel conveying systems.

Belts, sorting, and other criteria

First, a belt is a popular option for a parcel or package conveyor, as it can handle huge loads efficiently. The package surface generates friction on the product surface that creates a secure means of moving large amounts of differently shaped and sized items. But belts are less effective in applications that require singulation and/or accurate item placement. Norpak recommends roller conveyors in this case. If curves and bends are necessary, it is vital to invest in tight-centred, tapered rollers or belt curves.

But a parcel or package conveyor alone is not sufficient; also required is a full system to sort through parcels. Users need sortation solutions that carefully fit the facility’s needs. With manual sorting, a business must establish the labour requirements for the anticipated volume of packages. Automation systems lower the required amount of manual labour and offer higher efficiency while handling larger volumes, but are much more expensive and need extra maintenance and support. They also typically require substantial floor space.

Depending on the application and environment, other accessories and equipment many be necessary. For example, a scanning tunnel may be desired, and controlled gapping may be required to maintain steady material flow at high speeds. Otherwise, downtime during scanning may reduce the productivity of the whole system.

Users must ensure that systems can handle the speeds at which they operate. This involves not only choosing products with the appropriate speed rating, but also adopting maintenance and repair processes with minimal hassle. Norpak offers various kinds of conveyors designed to make maintenance and repair smooth, working with such notable manufacturers as Hytrol, Flo-Turn, and FMH.

To learn more, contact Norpak.

Share

Posted by Norpak Handling Limited

Norpak Handling provides conveying products and complete turn-key systems to suit your requirements and solve your probl... Read more