New WAGO proportional valve module offers high performance and efficiency

New WAGO proportional valve module offers high performance and efficiency

August 3, 2018 REDWIRE is news you can use from leading suppliers. Powered by FRASERS.

Posted by Wainbee Limited

Market demands for specialized services have allowed Wainbee Limited to enhance our offerings from its original industri... Read more

Subscribe

Free REDWIRE e-newsletter

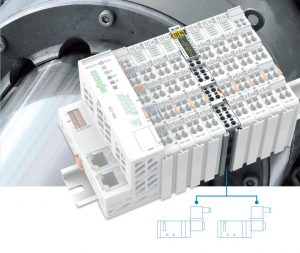

The WAGO-I/O-SYSTEM 750-632 proportional valve module, available from Wainbee.

Precision control is a key requirement for many industrial tasks; it necessitates the manufacture and distribution of tools and equipment that give users exacting control. This is why Wainbee Limited supplies such equipment for the Canadian marketplace – and one of the newest examples is the innovative WAGO-I/O-SYSTEM 750-632 proportional valve module.

The 750-632 specialty module is the perfect choice for heavy equipment that uses high-pressure pneumatic or hydraulic valves. WAGO recommends this proportional valve module for use in such industries as mining, oil and gas, heavy mobile equipment, metal forming, and aggregate.

Can handle multiple applications simultaneously

Encased in a 12-millimetre-wide housing, this compact module has two current-controlled pulse-width modulation 24-volt outputs, which enables efficient operation. Its reliable CAGE CLAMP connection technology helps users to save engineering time by making the module simple to configure, and with its configurable operating modes, one device can handle multiple applications at the same time.

WAGO has engineered this compact proportional valve module to control both pneumatic and hydraulic valves with flexible valve-control operation modes. It can control two single-coil valves or one dual-coil valve either uni- or bi-directionally, and the output current can be scaled up to 2A in a single-channel operation, or 1.6A in a two-channel operation.

Other notable advantages of using the WAGO-I/O-SYSTEM 750-632 module:

- Precise current control;

- Compatibility with any popular fieldbus, such as MODBUS TCP, Ethernet I/P, CAN, or PROFIBUS;

- Configurable characteristic curves, adjustable via parameters;

- User-friendly configuration and parameterization with WAGO-I/O-CHECK or with function blocks; and

- Compliance with several strict safety standards, including UL, ANSI, GL (for shipbuilding), Conformité Européene and cULus.

More features of the module include configurable dithering, adjustable ramping, and the ability to configure two additional digital inputs for multiple functions, like JOG, TRIP, or HOLD.

With all of these combined benefits, the WAGO-I/O-SYSTEM 750-632 module reduces system components, engineering, wiring, and commissioning hours.

About the companies

Headquartered in Minden, Germany, WAGO manufactures components for electrical connections and decentralized automation.

Wainbee Limited designs and provides solutions for engineered systems, motion and control, industrial filtration, and automation.

For more information, contact Wainbee.

Share

Posted by Wainbee Limited

Market demands for specialized services have allowed Wainbee Limited to enhance our offerings from its original industri... Read more