New drive series from Festo is perfect for lightweight applications

New drive series from Festo is perfect for lightweight applications

April 11, 2018 REDWIRE is news you can use from leading suppliers. Powered by FRASERS.

Posted by Festo Inc

Innovate today for a new tomorrow For nearly a hundred years Festo has provided proven Industry Leadership, Super... Read more

Subscribe

Free REDWIRE e-newsletter

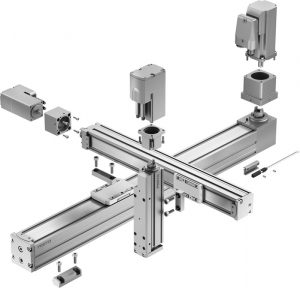

Festo's new ELGC/EGSC drive series is ideal for large-volume applications in limited space.

Festo’s diverse line of electric handling systems has just gotten even better, with the addition of the new ELGC/EGSC drive series. This group of electric drives and mini-slides provides an economical solution for industrial users who need high accuracy in lightweight, large-volume applications.

Among the low-cost options available in the ELGC/EGSC drive series are ELGC spindle and toothed belt axes, EGSC mini-slides, and axial and parallel kits of strategically paired servo and stepper motors.

Perfect choice for limited space

The latest innovation from Festo, the ELGC/EGSC drive series is recommended for many applications, including printed circuit-board production, desktop systems, electronics testing, pick and place sampling in medical laboratories, and even such sub-processes as handling, gluing and dispensing. These electric drives, mini-slides, and axes operate perfectly even under cleanroom conditions.

One of the many advantages of these new products is their compact design, along with their choice of motor kits, which makes them a perfect choice for applications involving limited space. In addition, they have a high performance drive and guide elements that carry large loads with ease and boast high repetition accuracy – accuracy as close as within 0.003 millimetres (mm) for spindle axes, 0.015 mm for mini-slides, and 0.08 mm for tooth belt axes. ELGC/EGSC drives, mini-slides and axes are strong enough to guarantee long service life.

Products in the ELGC/EGSC drive series all share a common platform architecture, which enables workers either to use them as single-axis systems or to join them to create cantilevers, pick and place solutions, linear gantries, or other multi-axis systems. Combining two ELGC drives or different types of mini-slides is simple and straightforward. Users can do this without needing any prior training or experience, nor even external adaptors or special assembly tools.

With their protected recirculating ball-bearing guides, the ELGC axes are perfect for XY movements and vertical Z movements, while the silent spindle operation of the EGSC mini-slides make them just right for Z movements and for guided linear individual movement in any mounting position.

The new ELGC/EGSC drive series is another stellar example of Festo’s mastery of industrial automation technology.

For more information, contact Festo.

Share

Posted by Festo Inc

Innovate today for a new tomorrow For nearly a hundred years Festo has provided proven Industry Leadership, Super... Read more