N.R. Murphy helps resin producer with new, self-cleaning dust collector

N.R. Murphy helps resin producer with new, self-cleaning dust collector

June 23, 2020 REDWIRE is news you can use from leading suppliers. Powered by FRASERS.

Posted by N.R. Murphy Limited

Since 1943, we have Experience In Custom Manufacturing Dust Collection Systems And Related Equipment. Also Includes: Cus... Read more

Subscribe

Free REDWIRE e-newsletter

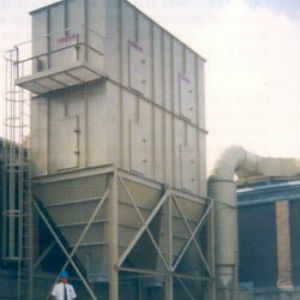

ACLO benefited from an N.R. Murphy dust solution.

It is hard to stay in business for over three-quarters of a century. To do so requires constant success with various customers. N.R. Murphy Limited has achieved this with its unparalleled range of air-quality solutions. A key example happened when ACLO Compounders, a custom compounder of thermoplastic resins, turned to the company to solve its dust problems. The N.R. Murphy team responded by recommending a powerful self-cleaning dust collector for the application.

To improve product quality

Airborne dust, including pigments and powders, was interfering with efforts to achieve an exacting colour-match system at the ACLO plant. This was not an occupational health and safety issue – the Ontario Ministry of Labour had classified the contaminants as non-toxic “nuisance dust”. Yet a new dust-collection system was required to improve product quality and enhance the overall working environment.

N.R. Murphy was one of many manufacturers with whom ACLO consulted, but it won the contract easily. ACLO senior technical/manufacturing manager Tom Stockford could see that the company’s long-term experience distinguished it from other suppliers, as did its ability to offer concrete ideas and suggestions throughout the planning process.

The recommended solution was the Model HEC-330-8 system. This was an automatic, continuous-duty, self-cleaning dust collector with twin top air inlets, top bag removal through walk-in plenum for convenient and inexpensive maintenance, an interior mounted compressed-air manifold, explosion-relief latched doors, a safety ladder, a platform and railings, and an inline duct silencer in the return air line. The Model HEC-330-8 had a capacity of 26,685 cubic feet of air per minute and a return-heat-to-plant exchanger. It measured ten by 20 by 31 feet and had a storage capacity of 85 cubic feet.

ACLO installed this self-cleaning dust collector immediately – and saw instant results. The Model HEC-330-8 met the manufacturer’s highest expectations, offering high quality with no disappointments. Such success stories are the norm with N.R. Murphy. The company typically attracts customers that make quality products, so they expect the same high standards in return.

With N.R. Murphy, expect the best air-quality solutions, always delivered and installed on time.

For more information, contact N.R. Murphy.

Share

Posted by N.R. Murphy Limited

Since 1943, we have Experience In Custom Manufacturing Dust Collection Systems And Related Equipment. Also Includes: Cus... Read more