Matritech works in four stages: engineering, design, finishing, delivery

Matritech works in four stages: engineering, design, finishing, delivery

August 31, 2020 REDWIRE is news you can use from leading suppliers. Powered by FRASERS.

Posted by Matritech Inc.

Matritech has the heart to remain ahead of all production for metallic pieces with technical specification. Continuing i... Read more

Subscribe

Free REDWIRE e-newsletter

Matritech is a major producer of custom parts.

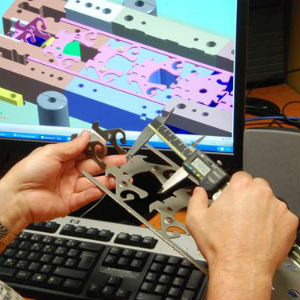

For more than 30 years, Matritech Inc. has been a top supplier of custom-made components. Businesses across the country approach Matritech as a one-stop shop for various machining services such as stamping, tooling, assembly, CNC machining, and more – all of them provided at the same facility in Drummondville, Que.

Customers get many competitive advantages with all these services and skills. Every project at Matritech goes through four stages: engineering, design review, finishing and surface treatment, and delivery.

Using Matritech’s collective expertise

The engineering phase is the first step in producing custom-made components at Matritech. The team uses advanced software for two- and three-dimensional design; these technologies allow the company to transfer electronic information from customers easily – and also to analyze dimension and tolerance carefully for the project. Engineers examine these analyses during manufacturing feasibility reviews and then apply them during the following phase, design. Matritech also uses software to program machine tools, thereby optimizing the use of material by proposing the best cutting configurations.

Design review is the next stage. Matritech uses its collective expertise to improve and optimize the development of the customer’s custom-made components. The concept review process allows the Matritech team to work directly with its customers to examine the design closely and figure out how feasible it is to make each product. The company’s experience and skill carry this stage, which leads to design enhancements and often lower costs.

Next comes finishing and surface treatment. A trusted team of strategic partners allows the company to sub-contract finishing and surface treatment to others. Among these tasks: painting, plating, silkscreen printing, anodizing, and preparing stainless steel for welding.

In the end, Matritech delivers the finished product. The company has a flexible MRP system that enables management of production as the team makes sure that it stocks the required materials and parts, delivers the products on time, and meets all of the client’s needs in the final outcome.

A reliable partner, fully committed to satisfying customer requirements, Matritech has perfected its system of creating industrial machine parts the right way each time.

For more information, contact Matritech.

Share

Posted by Matritech Inc.

Matritech has the heart to remain ahead of all production for metallic pieces with technical specification. Continuing i... Read more