Matcon’s six ways to save money by switching food-blending equipment

Matcon’s six ways to save money by switching food-blending equipment

April 12, 2018 REDWIRE is news you can use from leading suppliers. Powered by FRASERS.

Posted by Firing Industries Ltd

The business objective of FIRING INDUSTRIES LTD. is to consult with clients to select and supply technically complex PRO... Read more

Subscribe

Free REDWIRE e-newsletter

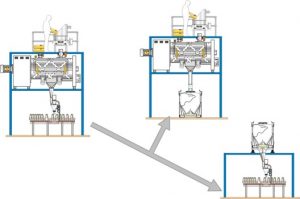

Matcon equipment for food processing -- including its intermediate bulk containers -- is available from Firing Industries.

Firing Industries has more than 45 years of experience in providing process equipment for users in many industries, including food processing. Like other manufacturers whose products Firing Industries supplies, Matcon – which provides intermediate bulk containers (IBC) for mixing applications – has ample expertise in its field. A recent blog entry by Matcon offers some valuable advice for manufacturers on how to tweak food blenders to make the mixing process more efficient – and save millions of dollars as a result.

Keeping ahead of the competition

Matcon suggests that getting the right food blenders is the key for companies to increase production and cut downtime. The company offers a six-point solution to increase production efficiency and stay ahead of competitors:

- Using a container-based mixing system. With an efficient system like Matcon’s line of IBCs, workers no longer need to mix more material than what has been ordered. A container-based system will reduce inventory and works in progress. Matcon’s IBCs are available in Canada from Firing Industries.

- Reduced storage space. With a lower inventory, a food-processing company now needs less storage room. This will save hundreds of square metres of warehouse space.

- Reduced waste. Less stock storage results in fewer materials expiring or being written off when market trends change. This leads to less wasted product.

- Using IBC food blenders. Only one IBC blender from Matcon is needed to take the place of five static industrial mixers. By making this switch, a company can save valuable floor space and capital.

- Reduced maintenance. Less equipment means less need for equipment maintenance, which saves a lot of time and expense.

- Reduced cleaning tasks. With container blending, workers do not need to clean between batch changes, which increases productivity and saves labour costs. With an IBC from Matcon, users will have less waste washed away if they discharge all of the product correctly.

With this system, food-processing companies can mix three or four batches in an hour instead of over an entire work shift.

To learn more about Matcon’s food-processing equipment, contact Firing Industries’ application-sales engineers at ddubuc@firing.com or (877) 688-0974.

Share

Posted by Firing Industries Ltd

The business objective of FIRING INDUSTRIES LTD. is to consult with clients to select and supply technically complex PRO... Read more