Linear actuators get various belting solutions through Megadyne-Jason

Linear actuators get various belting solutions through Megadyne-Jason

May 12, 2020 REDWIRE is news you can use from leading suppliers. Powered by FRASERS.

Posted by Jason Industrial (Canada) Ltd.

Rubber & Urethane Belting Used In Power Transmission & Synchronous Timing Belts, Industrial Hose & Couplings... Read more

Subscribe

Free REDWIRE e-newsletter

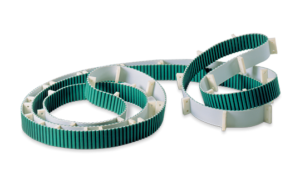

Megadyne-Jason makes two types of belts, with two materials, for linear actuators.

Megadyne-Jason is the premier source of industrial belting solutions, including timing belts for linear actuators. These devices are used in a broad range of industries, like packaging, material handling, robotics, pulp and paper, machine tools, elevators, the medical field, and the automotive sector. The company’s high-quality belts keep these businesses competitive.

To help customers learn about Megadyne-Jason’s belt options for actuator applications, the company offers a special e-book, downloadable at this link.

Rubber and urethane variations

Two variations of linear-actuator belting solutions are available – rubber and urethane. The appropriate type depends on the application. Megadyne-Jason’s rubber belts have the longest possible service life, but are subject to the material’s limitations and occasionally need replacement. Urethane offers better wear resistance and does not dry out, become brittle, crack, or dust out over time.

The two brands of timing belts for linear actuators, Megalinear and Megaflex, are both optimal for long-stroke actuation applications. Users can customize them for specific tasks, needs, and lengths. Among the most common options:

- 8M: with HF cords

- Urethane tooth shapes: MTD, RPP, STD, QST, GW, AT

- Rubber tooth shapes: RPP

- Cord constructions: S, HF, HP, HPF

To guide customers to perfectly customized belt fits, the engineering experts at Megadyne-Jason conduct careful analyses of many factors, including actuator speed, stroke length, acceleration and deceleration profiles, actuator carrier or clamp mass, noise-level requirements, design package, appropriate tooth shapes, cord structures, and application-specific material selection.

Megaflex timing belts are made with thermoplastic polyurethane and continuous spiral steel cords, which are ideal for power transmission and conveying heavy loads quickly. These belting solutions have a nylon coating on the teeth, which enhances running properties and lowers noise. Megadyne-Jason can also apply this coating for added thickness to the back of the belt, boosting protection against heavy products. Megaflex works for a wide spectrum of capabilities.

Also manufactured with thermoplastic polyurethane, Megalinear belts offer high resistance to wear and abrasion. Megadyne-Jason can shape this brand in various urethane options, like low temperature, high temperature, food grade, or different colours. Different cords and tooth designs are available.

For more information, contact Megadyne-Jason.

Share

Posted by Jason Industrial (Canada) Ltd.

Rubber & Urethane Belting Used In Power Transmission & Synchronous Timing Belts, Industrial Hose & Couplings... Read more