Kit Encoders by POSITAL now offer both absolute and incremental position control

Kit Encoders by POSITAL now offer both absolute and incremental position control

July 16, 2018 REDWIRE is news you can use from leading suppliers. Powered by FRASERS.

Posted by FRABA Inc

POSITAL-FRABA, based in Hamilton New Jersey, is the North American member of the international FRABA Group, a family of... Read more

Subscribe

Free REDWIRE e-newsletter

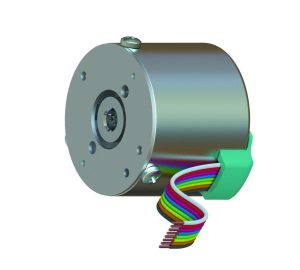

POSITAL kit encoders now can handle absolute motion control.

Since their introduction in 2017, POSITAL’s magnetic Kit Encoders have caught on widely with motor manufacturers and machine builders, providing a reliable, accurate, and cost-effective means of building rotary position feedback into products. Now, the company has improved encoders for servo and stepper motors, with new absolute-feedback models with similar mounting form factors as incremental kit encoders from other major producers.

With this upgrade, users can easily upgrade motion-control applications on these magnetic Kit Encoders from incremental to absolute position control.

Convenient new installation kits

The improved kit encoders come with easy installation kits that make motion-control upgrade simple and convenient. The closed-loop motor feedback gives users the advantage of absolute position feedback.

Control systems on POSITAL magnetic Kit Encoders always have full data on the physical positions of mechanical components being directed. Although absolute position feedback is a natural means of providing accurate position control, many current systems are designed around incremental encoders, since incremental feedback devices have usually been cheaper. Now that POSITAL absolute encoders are available at the same prices as conventional incremental encoders, system designers no longer need to adapt to the shortcomings of incremental feedback.

A key advantage of absolute encoders is that they measure position directly. While incremental encoders are good for speed-control applications, a controller must maintain an accurate count of pulses from the encoder to monitor absolute position. Positional accuracy can be lost if a power outage corrupts the pulse count, or if the control system does not update the count when the machine moves. Absolute encoders can re-establish knowledge of mechanical components’ positions by polling sensors and reading their rotational positions. This way, users never need to scrap work in progress or restarting systems.

POSITAL’s multi-turn absolute kit encoders have a magnetic sensing technology that offers robust encoder solutions, while the multi-turn counting system uses wire-energy harvesting technology that allows the encoder to keep true absolute position when the power is off. The encoders have 17 bits of single-turn resolution and 16 bits of multi-turn range.

Trust POSITAL for state-of-the-art technology in motion control.

For more information, contact POSITAL.

Share

Posted by FRABA Inc

POSITAL-FRABA, based in Hamilton New Jersey, is the North American member of the international FRABA Group, a family of... Read more