Industrial wave springs are available from Daemar in seven models

Industrial wave springs are available from Daemar in seven models

October 30, 2019 REDWIRE is news you can use from leading suppliers. Powered by FRASERS.

Posted by Daemar Inc.

Daemar manages the sourcing and delivery of millions of Essential Components to the manufacturing and MRO marketplace. I... Read more

Subscribe

Free REDWIRE e-newsletter

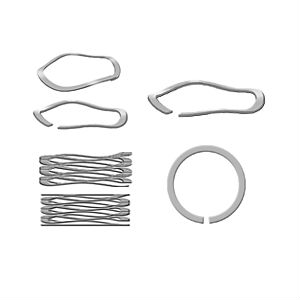

Daemar carries a wide range of wave springs.

Daemar Inc. has earned a longstanding reputation in the industrial landscape for its massive inventory of essential components. Customers have plenty of products from which to choose for sealing, retaining, protection, and other functions. One of Daemar’s lines of retaining components is industrial wave springs manufactured by TruWave. The many options available include single-turn and multi-turn models, as well as shim rings, with plain or shim ends and various sizes.

Saving space in radial direction

TruWave’s wave springs are constructed out of coiled flat wire, with a spring effect created by waves. There are many significant user advantages to this unique design: first, unlike with traditional coiled springs, half of the operating height can be reduced in axial direction, and second, industrial wave springs save more space in radial direction than disc springs do. Next, the bending load in the waves offers complete axial transmission of the load. Finally, wave springs also offer accurate spring rate and an unlimited range of forces.

There are seven types of TruWave industrial wave springs available from Daemar:

- Single-turn (inch) – The SST series is ideal for short deflection applications that involve low-to-medium force. These springs are built for a variety of bore and rod diameters and available in many waves and material thicknesses.

- Single-turn (narrow inch) – Also for short deflection applications, but with limited space.

- Single-turn (metric) – MST wave springs are like the SST line, with dimensions in millimetres.

- Multi–turn (inch) – Three series in this group (WSL, WSM, and WSR) designed for low-force applications with large deflections. More turns equal lower force. They use up less than half the spaces as helical compression springs do, but give the same amount of force.

- Multi–turn (metric) – The MWL, MWM, and MWR series are similar to the previous group, with dimensions in millimetres.

- Shim rings – KMS shim rings are manufactured to support, adjust for superior fit, or create a level surface. Also used as spacers for filling gaps between parts subject to wear.

- Nested wave springs – Similar benefits, but can be stacked on each other.

For more information, contact Daemar.

Share

Posted by Daemar Inc.

Daemar manages the sourcing and delivery of millions of Essential Components to the manufacturing and MRO marketplace. I... Read more