Hytrol produces three designs of pushers for diverting moving products

Hytrol produces three designs of pushers for diverting moving products

June 18, 2018 REDWIRE is news you can use from leading suppliers. Powered by FRASERS.

Posted by Norpak Handling Limited

Norpak Handling provides conveying products and complete turn-key systems to suit your requirements and solve your probl... Read more

Subscribe

Free REDWIRE e-newsletter

Norpak Handling supplies three types of pushers from Hytrol.

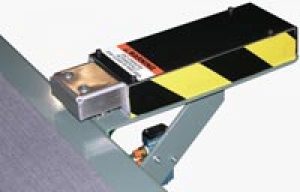

In addition to conveyors, Hytrol Conveyor Company manufactures many varieties of conveyor accessories – including pushers, used for diverting products off their course in a system. Available from Norpak Handling, a proud Integration Partner with Hytrol, these pushers can move items to different conveyors, different parallel lanes, or chutes.

Hytrol produces three different options for pushers, which vary by speed, weight of products being handled, design, and/or cost.

Easy for users to mount

The three types of Hytrol pushers that Norpak Handling offers:

- Light-duty (LD) pushers. Recommended mainly for rejection or inspection stations, these conveyor accessories are designed for easy mounting on the sides of many conveyor models, serving as an economical way of diverting lightweight products off at a right angle to the overall flow. Features include: aluminum pusher face; seven-, ten-, or 15-inch stroke; additional mounting hardware; and fewer electrical controls needed for actuation. Maximum carton weight of 15 pounds; not compatible with high-cycle applications.

- High-speed pushers (HSP). These pushers provide high-speed automatic product diversion at 90-degree angles onto other conveyors or chutes. Can handle speeds of up to 45 cycles per minute, depending on package weight and stroke length, with a unique, two-valve, pneumatic control system. Three different ranges of stroke length available, from 14 to 30 inches; can handle a maximum package weight of 75 pounds; double- and single-solenoid four-way valves; 1½-inch-bore double-acting air cylinder; 12-, 18-, or 24-inch-wide ram face with one-inch-thick cushioned pad.

- Overhead push-off. Like the HSP, this pusher offers high-speed automatic product diversion at a 90-degree angle onto another conveyor or a chute, but with a unique overhead design, which saves space next to the conveyor. Maximum package weight of 150 pounds; up to 20 cycles per minute; can work with packages between 4½ to 24 inches in height.

Other conveyor accessories manufactured by Hytrol include Y-switches, diverters, O-ring transfers, chain transfers, incline lift guides, and power-rotated turntables.

About the supplier

Founded in 1988, Norpak Handling Limited provides conveying solutions throughout all market sectors across North America. The company is based in Port Hope, Ont.

To learn more, contact Norpak.

Share

Posted by Norpak Handling Limited

Norpak Handling provides conveying products and complete turn-key systems to suit your requirements and solve your probl... Read more