How residual torsional stress ruins metal hoses, according to Hose Master

How residual torsional stress ruins metal hoses, according to Hose Master

August 24, 2020 REDWIRE is news you can use from leading suppliers. Powered by FRASERS.

Posted by Sudbury International Engineered Products Limited

Expansion Joints, (fabric, metal, rubber, dog-bone), Automatic Recirculation Valves For Pumps, Specialty Sootblowers, Se... Read more

Subscribe

Free REDWIRE e-newsletter

RTS is an issue that can be avoided, Hose Master says.

Sudbury International Engineered Products Limited supplies a wide selection of high-quality metal hoses by Hose Master. But even these great products are not completely infallible; torque and twisting can be a hazard. Torsional stress sometimes occurs during service, but one must also beware of residual torsional stress (RTS), which happens before installation.

A recent blog entry by Hose Master discusses how hose manufacturers can prevent RTS in metal hoses before it ruins them.

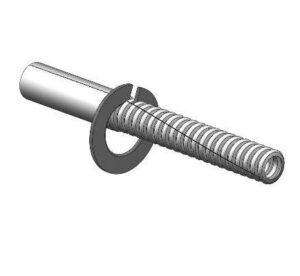

Visibly twisted seam weld

Residual torsional stress is inherent in many modern hose-forming processes. It accelerates metal fatigue, which reduces hose service life. One might even call it the Silent Killer of industrial metal hoses. A visibly twisted seam weld is a key sign of RTS. To prevent it, manufacturers must avoid certain production practices.

Helical forming is a hose-production method that employs a round disc twisted around a tube’s outer diameter to create a continuous helical corrugation. This process seems beneficial for being constant and inexpensive, but offers disadvantages too. Helical forming applies more stress to the metal when the hose is pressurized, so the helical corrugations try to straighten out by twisting. As a result, helical-formed hoses often do not last.

Cam forming is similar, except that the disc rotating around the tube to make the corrugations is split, which creates annular corrugations. But this technique also twists tubing while forming corrugations, resulting in the twisted seam typically associated with residual torsional stress.

Using helical or cam forming is inexpensive, but offers poor long-term cost savings; these hoses need to be replaced more often because of their short service life. Fortunately, Sudbury International supplies Hose Master solutions that avoid the RTS problem. The Hose Master team axially feeds these metal hoses during production, which effectively eliminates RTS and results in a longer-lasting and cost-efficient product.

Customers who are tired of replacing their metal hoses, wasting time and money, should put their trust in Sudbury International and its line of Hose Master products. These are RTS-free metal-hose solutions that last for years and contribute to the profitability of a company.

For more information, contact Sudbury International.

Share

Posted by Sudbury International Engineered Products Limited

Expansion Joints, (fabric, metal, rubber, dog-bone), Automatic Recirculation Valves For Pumps, Specialty Sootblowers, Se... Read more