Hosokawa Micron equipment optimizes graphite for cutting-edge batteries

Hosokawa Micron equipment optimizes graphite for cutting-edge batteries

December 8, 2023 REDWIRE is news you can use from leading suppliers. Powered by FRASERS.

Posted by Firing Industries Ltd

The business objective of FIRING INDUSTRIES LTD. is to consult with clients to select and supply technically complex PRO... Read more

Subscribe

Free REDWIRE e-newsletter

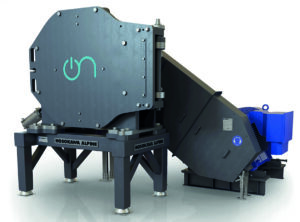

The Alpine Particle Rounder APR, by Hosokawa Micron

Firing Industries Ltd. offers a full range of processing equipment by Hosokawa Micron – including several devices specifically for enhancing energy-performance materials, especially graphite. This black, platelet-shaped mineral is the most important anode material in the production of lithium-ion batteries, and it is widely used for its plethora of manufacturing advantages.

To optimize the performance of batteries, manufacturers must make the best use of graphite. A variety of equipment by Hosokawa Micron can help them accomplish this.

High tap density, stable performance

The anode of a battery consists of a thick copper foil, measuring eight-to-18 micrometres and coated with graphite and various additives. Following coating, the graphite has relatively high tap density and relatively stable electro-chemical performance, while the actual specific capacity density can be near the theoretical value. But raw graphite also has an insufficient capacity to meet actual demand – which is expected to increase quickly in the near future.

To meet this long-term demand, battery producers must process graphite with minimal loss, so it can be used more effectively. Manufacturers must also advance graphite characteristics to boost battery performance. How quickly a battery can be charged and discharged depends on graphite particle size, and tap density determines energy density; in addition, the specific surface area influences the battery capacity following the first charge. Hosokawa Micron has developed technologies, available from Firing Industries, to advance graphite and achieve peak battery performance.

The appropriate graphite machine depends on whether the customer is processing natural or synthetic graphite. For pre-milling natural graphite, the Hosokawa team recommends the UPZ fine impact mill or the ZPS classifier mill. The ZPS is also useful for fine grinding or rounding, and the ACM classifier mill is also compatible with fine grinding. The Alpine Particle Rounder APR uses downstream classifying for graphite spheroidization. The UPZ is also recommended for pre-milling synthetic graphite, which can be ground by a ZPS or ACM. Both types of graphite can be mixed and coated with the Nauta and Cyclomix mixers and also coated with the Nobilita.

To learn more, contact Firing Industries’ application-sales engineers at ddubuc@firing.com or (877) 688-0974.

Share

Posted by Firing Industries Ltd

The business objective of FIRING INDUSTRIES LTD. is to consult with clients to select and supply technically complex PRO... Read more