High-pressure PTFE seals from Daemar designed for challenging work conditions

High-pressure PTFE seals from Daemar designed for challenging work conditions

September 21, 2023 REDWIRE is news you can use from leading suppliers. Powered by FRASERS.

Posted by Daemar Inc.

Daemar manages the sourcing and delivery of millions of Essential Components to the manufacturing and MRO marketplace. I... Read more

Subscribe

Free REDWIRE e-newsletter

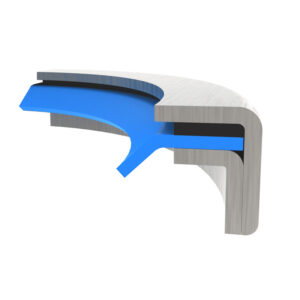

A DMR high-pressure PTFE seal

Daemar Inc.’s portfolio of essential components for industry includes the DMR line of high-pressure PTFE seals. These are robust, high-performance solutions designed for challenging work conditions. Reliable seals are crucial to modern industry, in which machinery operates under high pressure and extreme temperatures, which could damage equipment without sufficient protection.

Less downtime, higher efficiency, longer equipment life, and higher employee safety are among the advantages of using DMR high-pressure PTFE seals.

Chemical inertness, low friction

To thrive in demanding environments, each DMR high-pressure PTFE seal has a PTFE sealing lip and is metallic spring-free. The seals are manufactured to excel in extreme temperatures, high pressures, high speed, and corrosive fluid and gas. The Daemar team can even make the casings in stainless steel for the most demanding scenarios. Among the key features:

- Chemical inertness. PTFE resists many chemicals, acids, and bases.

- Low friction. PTFE has a very low friction coefficient, which minimizes wear and keeps operation smooth.

- High temperature resistance. PTFE withstands temperatures from cryogenic conditions to over 250 degrees Celsius, without losing sealing ability.

- Excellent insulation properties. PTFE is an excellent electrical insulator, making it compatible with electrical and high-voltage tasks.

- Non-stick surface. The non-stick surface properties make cleaning easier while eliminating contaminant buildup.

- High-speed operation. Seals retain integrity and performance at speeds as high as 45 metres per second.

PTFE is a versatile material with unique characteristics, and its ability to function in rough conditions makes it essential to applications in various sectors. It is smart to use quality PTFE seals when designing systems for high-pressure tasks, to ensure top performance, dependability, and worker safety. They demonstrate their value in demanding environments with the appropriate material selection and design considerations.

Daemar recommends its high-pressure PTFE seals for industries in which reliable sealing is crucial. Examples include oil and gas, aerospace, chemical processing, pharmaceuticals, and food processing. These seals can be found in valves, pumps, pipelines, hydraulic systems, fuel pumps, pharmaceutical-manufacturing machinery, high-pressure homogenizers, and processing or packaging pumps. They can be used to contain aggressive chemicals and maintain cleanliness.

For more information, contact Daemar.

Share

Posted by Daemar Inc.

Daemar manages the sourcing and delivery of millions of Essential Components to the manufacturing and MRO marketplace. I... Read more