Flowmax pump sealing technology by SAMES KREMLIN always stops leaks

Flowmax pump sealing technology by SAMES KREMLIN always stops leaks

May 28, 2019 REDWIRE is news you can use from leading suppliers. Powered by FRASERS.

Posted by SAMES KREMLIN

We are a World Leader in “Making Manufacturing More Competitive” with expertise in Finishing and Dispensing... Read more

Subscribe

Free REDWIRE e-newsletter

Flowmax feeding technology guarantees total sealing for leak-free pumps.

For well more than 90 years, SAMES KREMLIN has been revolutionizing industrial finishing by developing innovative new technologies. Although the company is known worldwide for its high-end paint-spraying solutions, it has also broken ground in the field of pump sealing technology – specifically, Flowmax, a method that guarantees total sealing for leak-free pumps.

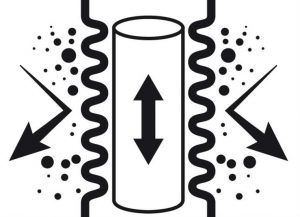

A bellow concept installed on the pump piston, Flowmax offers total reliability for the user when processing high solids, abrasives, UV, pre-catalized substances, water-based paint, or hardeners that contact isocyanate.

An unmatched level of reliability

As a patented SAMES KREMLIN design, Flowmax bellow technology improves the lifespans of pistons significantly. Equipment that is equipped with this pump sealing technology last far longer than traditional pumps with standard sealing do. The company has also adapted Flowmax to its spray guns, giving them an unmatched level of reliability.

By sealing pumps through bellow expansion and contraction, Flowmax guarantees zero material leakage and no moisture, air, or dust contamination. Because of the lack of packing or cartridge, the result is a maintenance-free pump with high durability; bellows can reach a lifetime of up to eight years or 10 million cycles.

SAMES KREMLIN uses Flowmax in many of its great high-end finishing products. These include Airmix and Airless paint pumps, circulating-system pumps, and dosing paint pumps.

One company that is extremely pleased with the results it gets from Flowmax is Gausdal Bruvoll, which manufactures traditional wood products in Gausdal, Norway. Employees of this company appreciate the full control that this pump sealing technology offers in painting applications; the flexibility to switch between paint colours within just a few seconds is another considerable asset that makes this company more productive and efficient. SAMES KREMLIN spraying equipment meets the challenge of extremely low monitoring, while being easy to use and maintain.

To hear Gausdal Bruvoll factory manager Truls Traseeth tell it in his own words (in Norwegian), check out this video:

For spraying technology that satisfies users all around the globe, always turn to SAMES KREMLIN solutions.

For more information, contact SAMES KREMLIN.

Share

Posted by SAMES KREMLIN

We are a World Leader in “Making Manufacturing More Competitive” with expertise in Finishing and Dispensing... Read more