Flexomix powder-agglomeration system by Hosokawa Micron enhances flowability, density

Flexomix powder-agglomeration system by Hosokawa Micron enhances flowability, density

August 3, 2023 REDWIRE is news you can use from leading suppliers. Powered by FRASERS.

Posted by Firing Industries Ltd

The business objective of FIRING INDUSTRIES LTD. is to consult with clients to select and supply technically complex PRO... Read more

Subscribe

Free REDWIRE e-newsletter

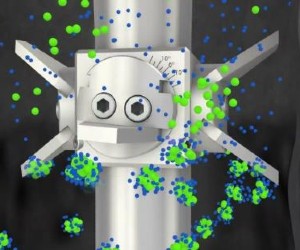

The Hosokawa Micron Flexomix solution

Hosokawa Micron processing solutions are available from Firing Industries Ltd., including the Flexomix powder-agglomeration system. A compact installation for continuous mixing and agglomeration of powder with fluids, the Flexomix solution uses innovative agglomeration technology to enhance flowability, wettability, dispersibility, bulk density, and product appearance. It creates granulates with a porous, raspberry-like structure, high solubility, and excellent flow properties. Customers unlock new possibilities for their businesses by adapting Flexomix to their individual requirements.

The peak of agglomeration

Agglomeration is also referred to as wet granulation or particle-size enlargement, and the Flexomix offers the peak of agglomeration by combining two proven Hosokawa Micron technologies: the Flexomix continuous mixer/agglomerator and the Schugi fluid bed dryer and cooler. This blended design results in the ultimate powder-processing system that gives operators optimal process control. The system offers capacities from 50 to 40,000 kilograms per hour.

The Flexomix system allows users to produce porous agglomerates ranging from 100 to 1,500 microns, with a typical D50 value from 200 to 700 microns. Since this system from Firing Industries is used extensively for the creation of instantly soluble agglomerates for food, chemicals, and pharmaceutical tasks, this technology is sometimes called instant agglomeration. Base powders can be fed as a mixture or multiple powders in parallel. An accurate, gravimetrical powder-feeding subsystem ensures a consistent powder-to-liquid ratio, and a fluid-dosing skid ensures accurate flow control and a constant powder-to-liquid ratio in the agglomerator. The fluid skid can be equipped with a stirrer or heated tank, or even with a preparation tank in applications involving solution binders.

The Flexomix mixer/agglomerator is popular with businesses for its reliability, simplicity, compact design, and maximum process flexibility to make the needed agglomerates. It allows homogeneous mixing of powder and liquids to make wet agglomerates immediately. The Schugi fluid bed dryer dries, cools, and conveys the agglomerates to the product-classifying section to prepare the final product.

To get a better idea, check out the video below:

To learn more, contact Firing Industries’ application-sales engineers at ddubuc@firing.com or (877) 688-0974.

Share

Posted by Firing Industries Ltd

The business objective of FIRING INDUSTRIES LTD. is to consult with clients to select and supply technically complex PRO... Read more