Flat wire wave springs by Daemar offer many compelling advantages

Flat wire wave springs by Daemar offer many compelling advantages

December 7, 2020 REDWIRE is news you can use from leading suppliers. Powered by FRASERS.

Posted by Daemar Inc.

Daemar manages the sourcing and delivery of millions of Essential Components to the manufacturing and MRO marketplace. I... Read more

Subscribe

Free REDWIRE e-newsletter

Flat wire wave springs replace other kinds of springs.

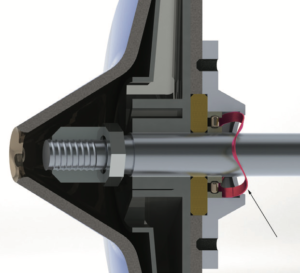

Daemar Inc. supplies essential components for industry, including flat wire wave springs – both single- and multi-turn options. Users get the ultimate balance of size and spring force from these units. Although most engineers are experienced with traditional coil and disc springs, they get many compelling advantages from wave springs. They offer benefits in assembly, with the ability to self-locate in bored holes or on shafts.

Consistent force across many deflections

Another major advantage is the high force-to-work height ratio. Wave springs can cause forces equal to or higher than those of coil springs. When well-designed, they create a more consistent force across many deflections; their deflection curves have a wider, flatter linear force region than coil or disc springs offer. Wave springs transmit these forces only in the intended axial direction, without the torsional loading and twisting that hamper coil springs.

Two types of flat wire wave springs are available from Daemar: single-turn and multi-turn. Single-turn wave springs typically replace stamped wave washers in such applications as preload, connector and fluid power seals, and noise and vibration attenuation. Multi-turn wave springs are recommended for mechanical seals and various power-transmission and fluid power systems in automotive, medical, or industrial equipment. These springs usually replace coiled springs or disc-spring stacks.

Flat wire wave springs can improve the performance of spring-loaded components as drop-in replacements for traditional spring elements. To maximize their engineering potential, these units should be designed around the following qualities:

- Axial space savings. Wave springs usually need only half the work height of coil springs to deliver the same force.

- Consistent spring force. A typical linear force between 30 and 70 per cent deflections.

- Dimensional-tolerance improvements. A cost advantage of wave springs is the ability to loosen dimensional tolerance on spring cavities and shafts.

- No torsional loads. No issues with rotational wear, like those with seals.

- Higher travel. Multi-turn wave springs can offer up to five centimetres of travel.

- Dial in required stiffness. Wave springs can eliminate hysteresis.

- Quick customization. Manufacturers can customize wave springs on the fly.

For more information, contact Daemar.

Share

Posted by Daemar Inc.

Daemar manages the sourcing and delivery of millions of Essential Components to the manufacturing and MRO marketplace. I... Read more