The five construction styles of braided packing available from Daemar

The five construction styles of braided packing available from Daemar

March 7, 2018 REDWIRE is news you can use from leading suppliers. Powered by FRASERS.

Posted by Daemar Inc.

Daemar manages the sourcing and delivery of millions of Essential Components to the manufacturing and MRO marketplace. I... Read more

Subscribe

Free REDWIRE e-newsletter

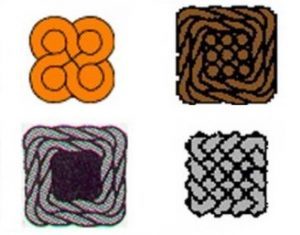

Daemar supplies braided packing in five different styles of construction.

Among the impressive breadth and variety of essential industry components distributed in Canada by Daemar Inc. – an inventory that includes a wide range of seals, retainers, slides, protective caps and plugs, and more – is a plethora of braided packing. These materials are generally used to stuff boxes for pumps to seal all kinds of fluids.

Before settling on what braided-packing products to invest in, it is wise to consider what design of packing is best suited for a company’s specific operating environment. Daemar carries 29 styles of braided packing in five different types of braid construction.

Narrowing down the selection

Braided packing is created by braiding yarn, ribbons, ravings, and other materials in different ways. The five main styles of braiding:

- Square-braided. Also called square-plaited, this form of braiding involves equipment that passes strands of material over and under strands running in the same direction, which typically results in a square or rectangular cross-section in the packing. This style of packing is often soft, can hold a lot of lubricant, and is ideal for high-speed rotary service at low pressures. Recommended for old or worn equipment.

- Braid over braid. Referred to by some as round or multiple braiding, this is performed by a machine that braids tubular jackets with multiple materials either alone or in combination. Braiding jackets one over the other yields the size of the packing, which comes in round, square, or rectangular cross-sections. This dense packing is ideal for valve stems, expansion joints, groove gasketing, and other high-pressure, slow-speed applications.

- Braid over core. This braiding technique involves braiding one of more jackets of materials over a core, which can be twisted, wrapped, knitted, or extruded. A variety of densities and cross-sections are possible here.

- Interbraid. Braiding equipment criss-crosses strands of different materials, either alone or in combination, from the surface diagonally through the packing body. The strong locks between strands create a dense integral structure that stays together, yet remains flexible.

- Die form. In this pre-compressed ring form, many compression packing materials are available for controlled density and size.

To learn more, contact Daemar.

Share

Posted by Daemar Inc.

Daemar manages the sourcing and delivery of millions of Essential Components to the manufacturing and MRO marketplace. I... Read more