Festo’s SBRD smart camera system is simple yet very flexible

Festo’s SBRD smart camera system is simple yet very flexible

December 9, 2019 REDWIRE is news you can use from leading suppliers. Powered by FRASERS.

Posted by Festo Inc

Innovate today for a new tomorrow For nearly a hundred years Festo has provided proven Industry Leadership, Super... Read more

Subscribe

Free REDWIRE e-newsletter

The SBRD smart camera system by Festo

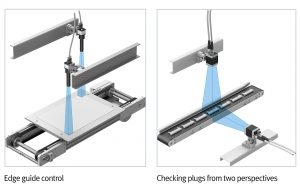

The newest technological breakthrough from Festo Canada is the SBRD smart camera system: a cost-efficient solution for quick, reliable inspection. What distinguishes this product is that it is easy to set up and operate, even for novices, but offers unmatched flexibility for professional users, covering many fields of analysis, tracking, and verification for automation and robotics. The system can conduct a variety of applications that require a multi-camera approach.

Fanless remote head controller

The SBRD is made up of the following three elements:

- Extremely lightweight, compact, high-resolution USB cameras that create monochrome or colour photos with up to five megapixels of resolution;

- Specially designed, space-optimized, yet powerful controller with two camera interfaces; and

- Camera Configuration Studio (CCS), exclusive image-processing software for quick, process-reliable results.

The fanless remote head controller is optimized for multi-camera applications. It comes with a dual-core processor and PROFINET communications. The two camera interfaces enable inspection from multiple perspectives with large fields of view. The SBRD can run many inspections and functions, allowing it to check pattern matching, brightness, colours, data-matrix-codes or barcodes, pixel cloud location, circle and edge finding, optical character reading, and other characteristics.

Users of this smart camera system by Festo can configure inspection programs and define, log, and adjust all processes from image recording to the input and output parameters (and simulate them in advance on a PC), all using CCS. The software uses image analysis and lists, instead of individual photos, to process images. This setup process is far simpler than those of most conventional inspection systems are; users merely take different sample pieces and record them, then define exactly what they need to analyze and how to do it. The tolerance ranges are based on the results data of the recorded images, but the operator can make alterations.

In addition, the CCSxRun tool allows users to parameterize test tools quickly; settings required configuration only once, and then the smart camera system applies them to all detected objects. The result is easier program development and maintenance and neat, tidy program structure.

For more information, contact Festo.

Share

Posted by Festo Inc

Innovate today for a new tomorrow For nearly a hundred years Festo has provided proven Industry Leadership, Super... Read more